Projects

Here is an overview of all the most interesting tech projects I've worked on

recently, although some have been omitted due to a lack of pictures or an

unsatisfactory conclusion.

Water Purification

I was talking with a friend about the water crisis, specifically in

Cape Town, and she argued that many of humanity's biggest problems will

not be solved unless millions of people can work together and put their

individual interests second. Given how unlikely this is to happen, I would

argue that only money and science can provide the alternative solutions

that we need. This project (which falls under the second category) is my

contribution to the solution.

The goal of this project was to distil potable, clean water from seawater,

with a low energy cost. Generally, distillation is extremely inefficient

because so much of the heat is lost to the environment. However, if the

boiling point of water can be reduced to a temperature that can easily

be generated by sunshine, then inefficiency would be inconsequential.

By generating a vacuum in the still, then the difference between the vapor

pressure of the water and the atmospheric pressure will be much lower, and

less energy will be required to boil the water.

Here is a mockup I did in Fusion 360:

The seawater is stored in one side, the valves are closed, and a pump attached

to the vacuum hose is used to decrease the pressure in the apparatus to

the about 21 mmHg, or the vapor pressure of water. When this pressure is

reached, the water will boil until the pressures equalize again. If one

side is heated and the other is not (accomplished by painting one side black

and the other silver), then the water in the hot side will boil, reach the

refrigeration coil, and condense into the other side.

The seawater is stored in one side, the valves are closed, and a pump attached

to the vacuum hose is used to decrease the pressure in the apparatus to

the about 21 mmHg, or the vapor pressure of water. When this pressure is

reached, the water will boil until the pressures equalize again. If one

side is heated and the other is not (accomplished by painting one side black

and the other silver), then the water in the hot side will boil, reach the

refrigeration coil, and condense into the other side.

$100 and a trip to the hardware store later, I have all the components I

need.

The final parts list was:

The final parts list was:

- 2ft of 2in pvc piping

- 6in of 1/2in pvc piping

- 2in pvc end cap

- 3 2in pvc couplings

- 2ft of 2in pvc piping

- 3 2in to 1in pvc reducing adapters

- 3 1in to 1/2 in reducing adapters

- 2 1/2in pvc to 1/2 in steel male threaded adapters

- 2 steel 1/2 in Ts

- 2 1/2 in to 3/8 in compression fittings

- 1 1/2in to 3/8in steel reducing adapter

- 1 1/2 in ball and socket valve

- 1 1/2in steel pipe nipple

- 1 pressure gauge with a 3/8 in male stem

- 2ft of 2in pvc piping

- 10ft of 3/8in refrigeration coil

- 10 ft of 3/8in vacuum line

- 1 1/2in to 3/8in barb fitting

- 1 1/2in pvc ball and socket valve

I started by assembling the pvc components, allowing them time to dry while

I screwed together the metal components, using Teflon tape to seal each of the joints.

All in all, the project only took one day to complete (excluding testing).

All in all, the project only took one day to complete (excluding testing).

Of course, this prototype is not suitable for continued use - the pcv would

deteriorate in the sun and the volume is too small - but it will work well

for testing. The saltwater side (with the ball and socket valve) will be

painted black so it heats up in the sun, and the volume of water in the

other side will be used to determine the efficiency over time.

Of course, this prototype is not suitable for continued use - the pcv would

deteriorate in the sun and the volume is too small - but it will work well

for testing. The saltwater side (with the ball and socket valve) will be

painted black so it heats up in the sun, and the volume of water in the

other side will be used to determine the efficiency over time.

The next step was to create a vaccum pump that could be replicated easily

and at low cost. A brief internet search yielded many many results, and I

decided to construct a pump using a cheap bike pump. Online, many people

had described rotating the valves around to change the flow of air, but

the pump that I purchased was too cheap and had the valves built into the

plastic.

To reverse the pump, I started by flipping over the seal on the inside of the

plunger so that it would allow air to flow in only on the downstroke.

I could now crush water bottles, but without the one way valve at the

bottom, I couldn't get more than one stroke. To fix this, I used NighHawkInLight's design

for one way valves with some pieces of an inner tube for a bike, and it worked

splendidly!

I could now crush water bottles, but without the one way valve at the

bottom, I couldn't get more than one stroke. To fix this, I used NighHawkInLight's design

for one way valves with some pieces of an inner tube for a bike, and it worked

splendidly!

Now I'm only waiting for a new negative pressure gauge: after that arrives,

I can begin testing.

Now I'm only waiting for a new negative pressure gauge: after that arrives,

I can begin testing.

The High Altitude Balloon

This project was for an Aerospace class at East High

School, which aimed to obtain pictures of the curvature of the Earth and

collect data on various atmospheric pollutants on the way.

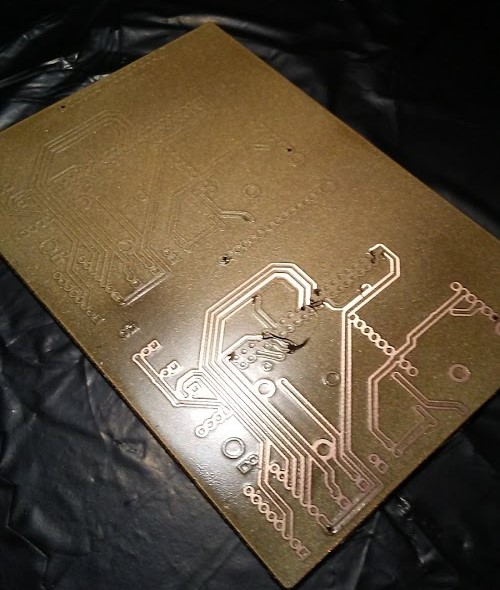

The balloon project will only be discussed here in its capacity as the most

complicated PCB design and fabrication I have ever done. Other information

can be found on the HAALO website or through East High School.

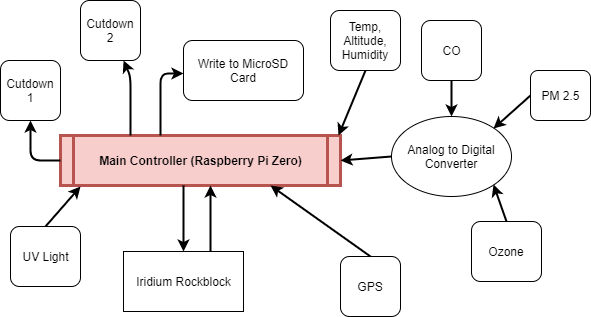

All of the electronics for the balloon were custom built and designed

specifically for this project. We started by identifying all of the functions

that we wanted to be able to perform...

- Communicate with the ground station

- Read its position using GPS

- Measure temperature, pressure, and humidity

- Measure ozone, carbon monoxide, and particulate matter levels

- Take and transmit pictures taken during flight

- Cut down the balloon if necessary, as required by the FAA

- Save all flight data to a microSD card

- Facilitate easy retrieval (using a beeper or light)

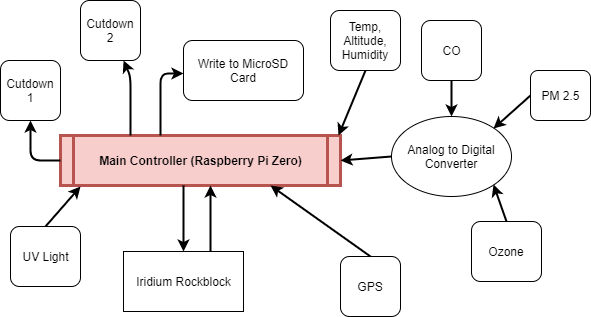

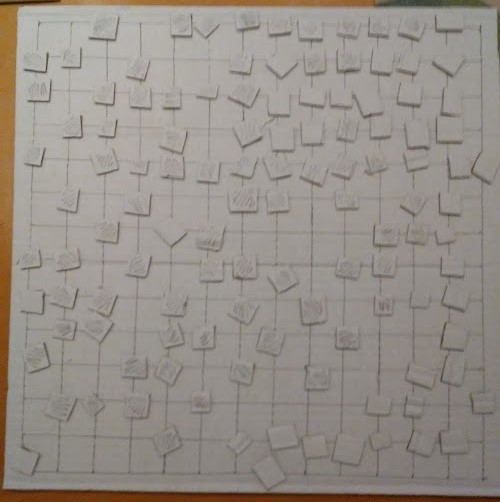

...and then creating a diagram to show the flow of information between

each system:

We decided that it would be easier to manage and test the computer if we

created a printed circuit board for it, especially given my experience with

the breadboard STM. I had only very limited experience with etching

PCBs using ferric chloride, and even less with

Fritzing, but we were not to be

deterred!

We decided that it would be easier to manage and test the computer if we

created a printed circuit board for it, especially given my experience with

the breadboard STM. I had only very limited experience with etching

PCBs using ferric chloride, and even less with

Fritzing, but we were not to be

deterred!

Given tight budget constraints (other groups of students were working on

obtaining funding, and deserve great praise for their hard work and genius),

we created the parts list before we finished the schematics. For those who

are interested, it can be found

here.

After only a few weeks of planning, the outreach team secured over $2,000

for the completion of the project! All parts were ordered, and we began

work on the schematics. After struggling to find parts that were already

present in the Fritzing libraries, we switched to Altium Circuitmaker

(another free PCB design software) because it had better support for custom

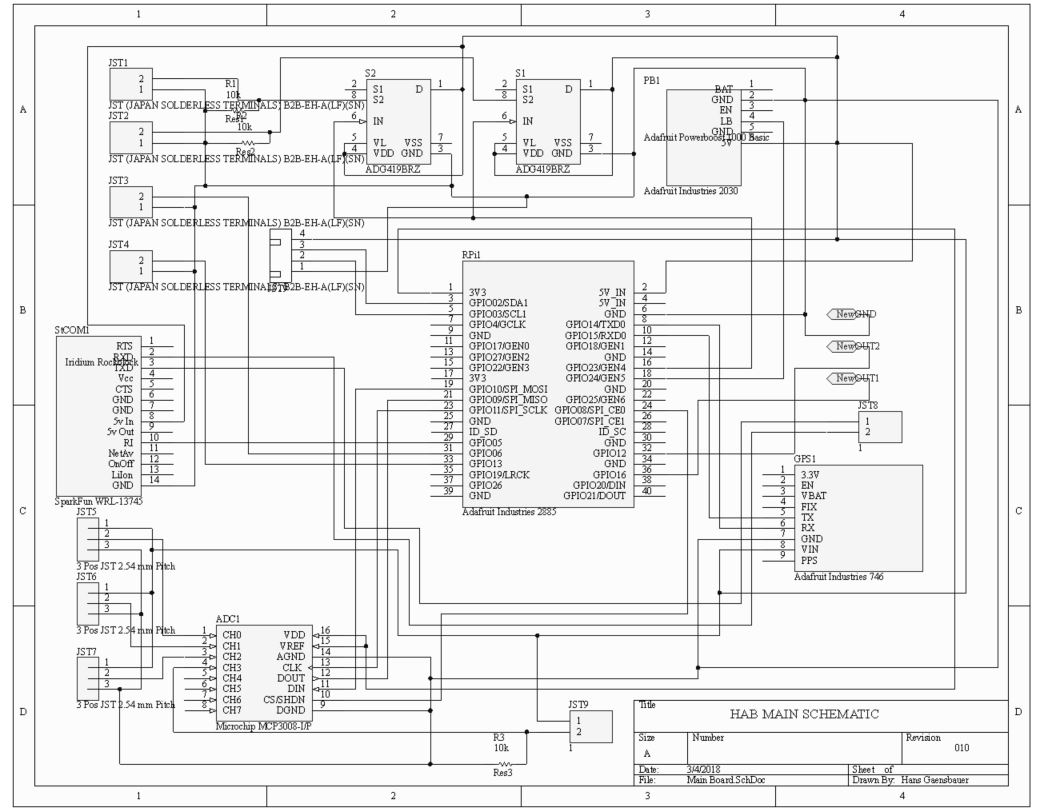

components. Here is the schematic, version 10:

By using JST connectors for all of the sensors, the computer could be kept

warm within the housing while the sensors were exposed to the environment

(so they can take data). Unfortunately, the complexity of the board combined

with size constraints meant that the PCB would have to be double sided -

a unique challenge in alignment.

By using JST connectors for all of the sensors, the computer could be kept

warm within the housing while the sensors were exposed to the environment

(so they can take data). Unfortunately, the complexity of the board combined

with size constraints meant that the PCB would have to be double sided -

a unique challenge in alignment.

The general process for creating a PCB is as follows:

- Create a design for a PCB on Circuitmaker, Fritzing, et cetera

- Spray paint a sheet of copper clad laminate

- Use a laser engraver to etch the negative of the PCB design, with careful scaling

- Expose the PCB to ferric chloride, which will oxidize the copper

- Use a micro drill bit to drill holes in each of the pads

- Fit each of the through holes and vias with rivets

This is a screenshot of the design from Altium Circuitmaker. I excluded the

polygon pour (which means less acid is necessary to etch the PCB)

so that the bottom layer (shown in blue) is more visible. I used a plastic

based spray paint that I found at work to cover the PCB, and clamped it so

that it could dry.

I've found that certain spraypaints work better than others when being

etched on a laser, and I've found that running the job twice helps to clear

up a lot of the residue that would slow down the etching process.

I've found that certain spraypaints work better than others when being

etched on a laser, and I've found that running the job twice helps to clear

up a lot of the residue that would slow down the etching process.

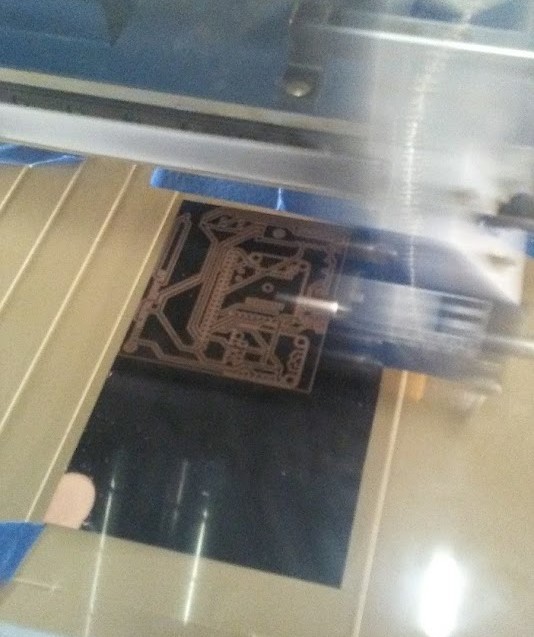

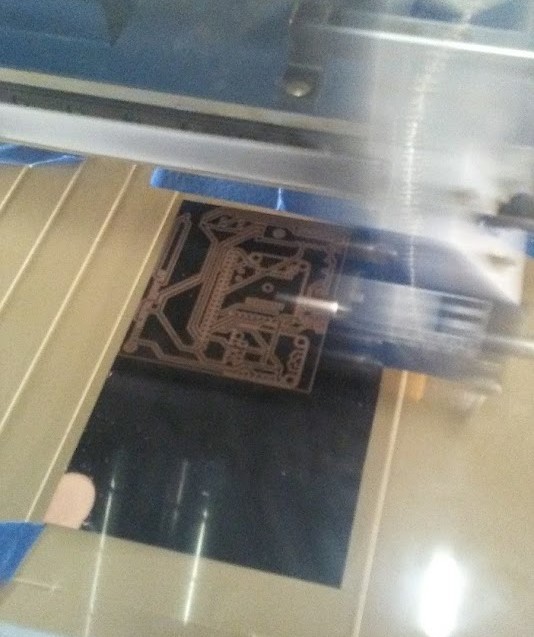

This is the PCB while it was being etched in a 60 watt Epilog Fusion. By

cutting a rectangle with the dimensions of the PCB blank, pretty precise

alignment is possible. When one side was finished, the PCB was flipped over

to etch the opposite side.

This is the PCB while it was being etched in a 60 watt Epilog Fusion. By

cutting a rectangle with the dimensions of the PCB blank, pretty precise

alignment is possible. When one side was finished, the PCB was flipped over

to etch the opposite side.

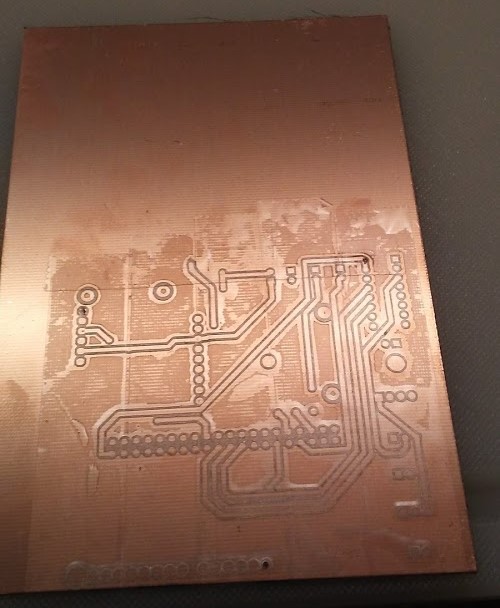

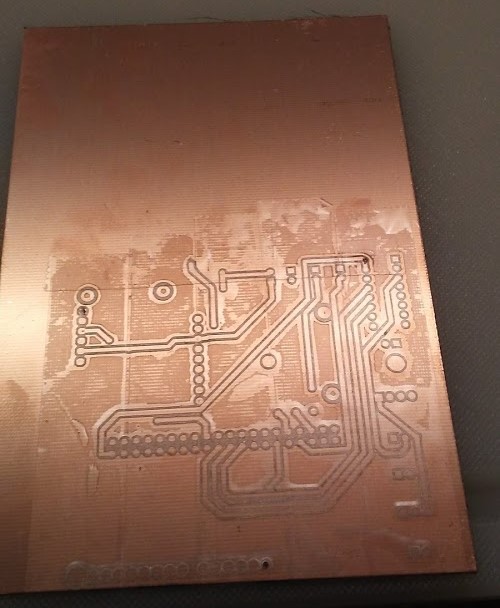

After the PCB had been etched, it was possible to see through the laminate

in the areas where copper had been removed from both sides (such as around

vias and headers). Unfortunately, it was pretty clear that the two sides were

not perfectly aligned, and further inspection indicated that the PCB blanks

were not really rectangular.

This was only the beginning of our problems - but we did find a solution.

By painting only one side of the board, holes drilled in 3 vias could be

used to align a vinyl cut negative on the other side. I spray painted over

this and peeled off the vinyl before it was dry, then etched the PCB with

ferric chloride as usual.

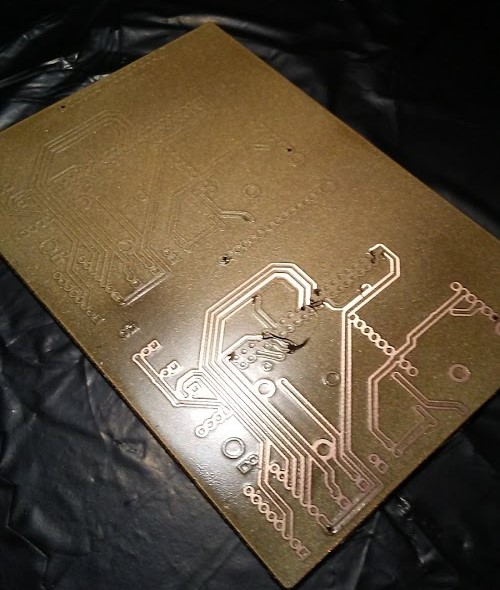

After etching and assembling this PCB, we realized that our sensors were

all digital devices, not analog ones. We are still in the process of creating

a new revision.

After etching and assembling this PCB, we realized that our sensors were

all digital devices, not analog ones. We are still in the process of creating

a new revision.

scatter.cloud

Scattercloud is, at its simplest, a blockchain. The scatter.cloud blockchain

(hereafter SCA) is designed to facilitate fast and byzantine fault tolerant

transactions between clients on the network, using a derived consensus model

for mitigating forks in the blockchain. Information on the development of

SCA will be posted here, as well as code and instructions for accessing and

developing on the blockchain.

Scattercloud is, at its simplest, a blockchain. The scatter.cloud blockchain

(hereafter SCA) is designed to facilitate fast and byzantine fault tolerant

transactions between clients on the network, using a derived consensus model

for mitigating forks in the blockchain. Information on the development of

SCA will be posted here, as well as code and instructions for accessing and

developing on the blockchain.

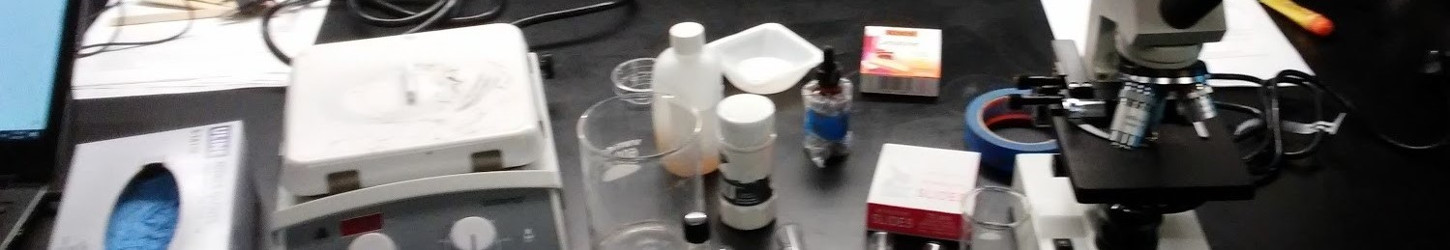

Microscopes

I love microscopes! I was (and still am) inspired by the things they reveal,

and with such simplicity! I've had a number of opportunities to design

modifications to a cheap brightfield microscope, and I've compiled them here.

These modifications have bene tested on Zenith school microscopes and an

AmScope brightfield microscope I have access to at home.

I have also included a discussion of a variant of

Dan Berard's STM I built a while ago, and a few other microscope hacks

I've found and tested. Most of the images are of tissue paper at 100 to 400

times magnification.

These pictures show a phone camera mount for a microscope that I designed in

FreeCAD. The mount is inspired by

ggoss' Universal Camera Phone/Microscope Adapter on Thingiverse, and

was used to take all of the pictures in this section. For those who are

interested, the STEP file can be downloaded here.

These pictures show a phone camera mount for a microscope that I designed in

FreeCAD. The mount is inspired by

ggoss' Universal Camera Phone/Microscope Adapter on Thingiverse, and

was used to take all of the pictures in this section. For those who are

interested, the STEP file can be downloaded here.

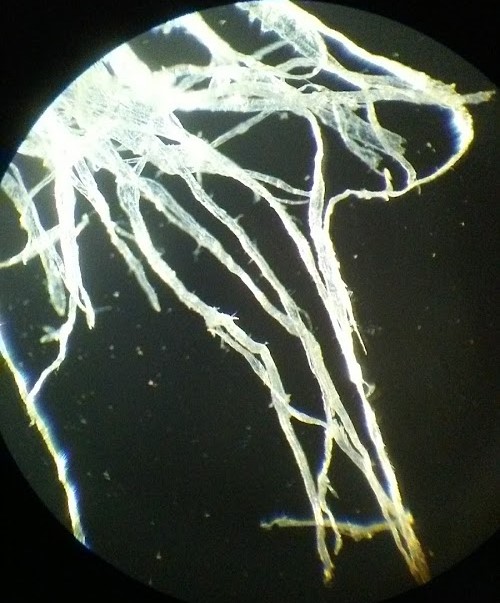

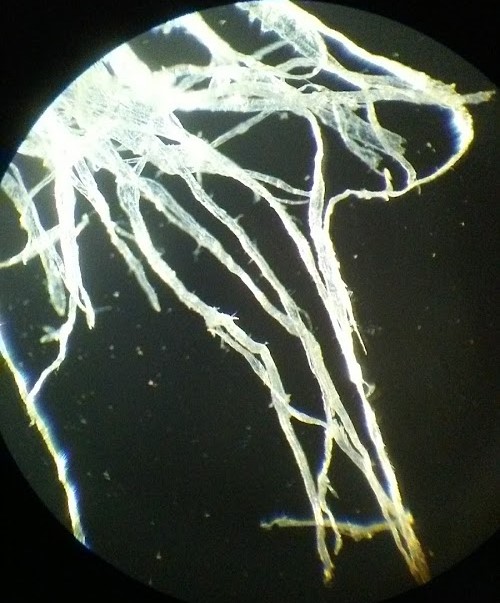

The first modification changes a traditional brightfield microscope into

a darkfield microscope, which provides better contrast by showing an

illuminated sample on a dark background.

Brightfield microscopes block the light coming directly up through the

condenser, so that the only light that passes the sample would miss the

objective lens. However, some of the light that hits the sample is

diffracted, and passes into the lens. Only the sample causes the light to

be redirected, so the sample glows on an otherwise dark field, hence the name.

This design is an improvement on the "One-Penny Darkfield Illumination Filter",

described here.

The disk is designed to fit inside the diaphragm of a Zenith microscope,

so that a user can switch between darkfield and brightfield by rotating the

diaphragm. Here are the results:

The disk is designed to fit inside the diaphragm of a Zenith microscope,

so that a user can switch between darkfield and brightfield by rotating the

diaphragm. Here are the results:

These images are good for illustrating the differences between the two

microscopes, but they are poorly focused (my piece of tissue paper was not

very flat). Better clarity can be achieved using a slide and a smaller

sample:

These images are good for illustrating the differences between the two

microscopes, but they are poorly focused (my piece of tissue paper was not

very flat). Better clarity can be achieved using a slide and a smaller

sample:

The details become much easier to see under a darkfield microscope (and they

look cooler too!). The file for the occulting disk is here.

The details become much easier to see under a darkfield microscope (and they

look cooler too!). The file for the occulting disk is here.

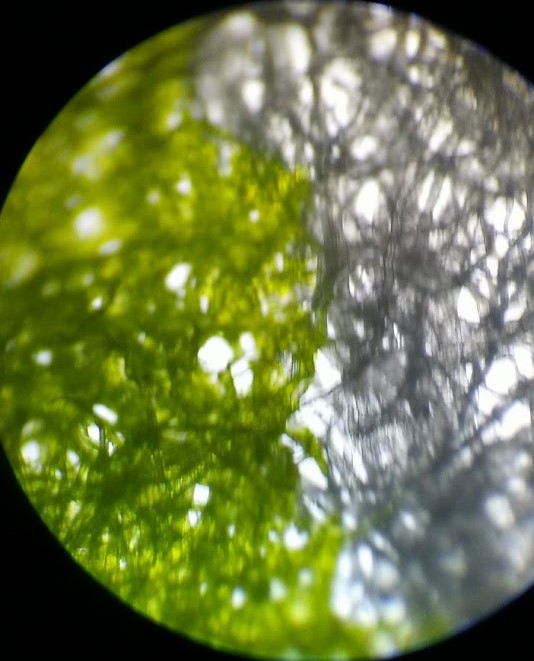

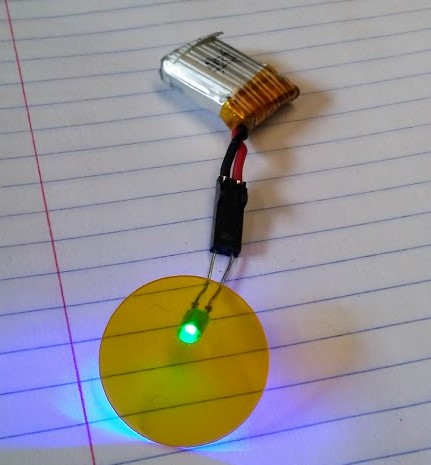

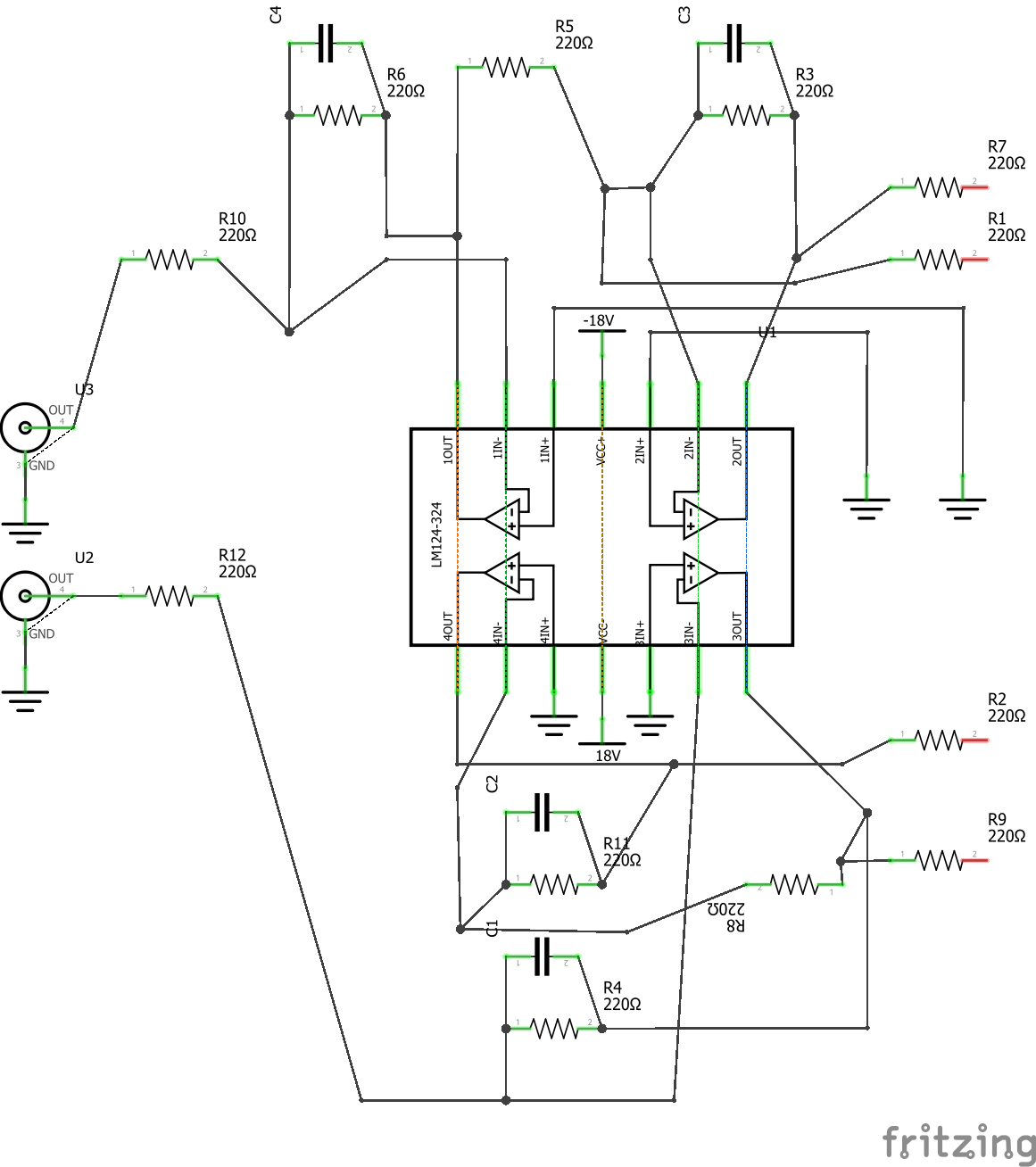

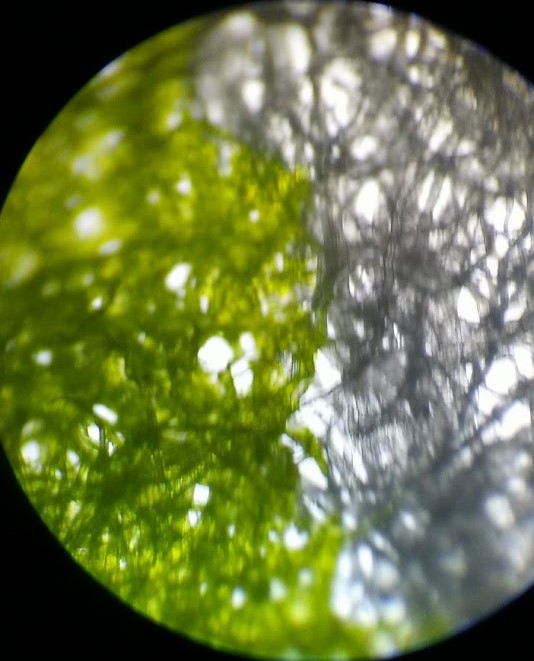

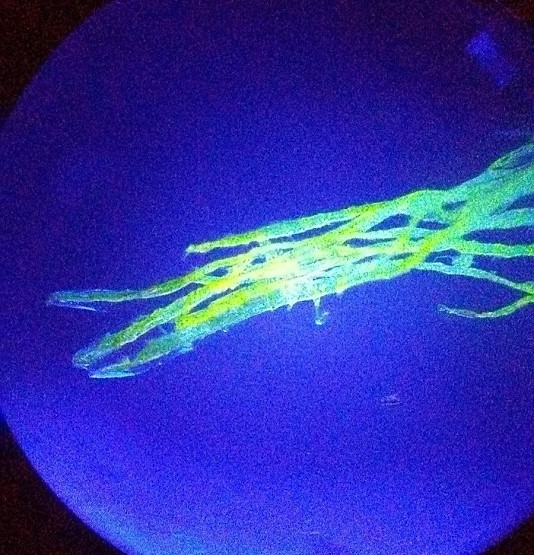

The next hack is much more interesting, but the lack of an appropriate sample

makes the images slightly less picturesque. By illuminating a flourescent

sample with UV light, it can be caused to glow. By using a highpass filter

to block the UV light, only the light from the sample is visible, so certain

proteins or indicators (like GFP) can be used.

For each of these samples, I used tissue paper that had been marked with

highlighter, because it was flourescent (and I could not afford or effectively

use flourescent samples).

This image shows the contrast between the flourescent (highlighted)

and normal fibers in a brightfield microscope. The image is poorly focused

because the sample was too large, and the highlighter prevented me from using

water or a coverslip.

This image shows the contrast between the flourescent (highlighted)

and normal fibers in a brightfield microscope. The image is poorly focused

because the sample was too large, and the highlighter prevented me from using

water or a coverslip.

The first iteration of this design was created using a stack of purple plastic

rectangles cut from a divider in one of my binders, and a set of safety

glasses with yellow lenses. The purple sheets were placed on top of the

light beneath the stage, and acted as a filter.

It worked! Sort of. Although the highlighted side is much more clearly distinguishable,

ideally, the non-flourescent areas should be invisible. Additionally, using

a filter to create high frequency light assumes that the microscope's bulb

already produces light of that wavelength. I removed the lens on the bulb on the

AmScope microscope, and its tungsten filament bulb worked. The Zenith school

microscopes did not work so well.

It worked! Sort of. Although the highlighted side is much more clearly distinguishable,

ideally, the non-flourescent areas should be invisible. Additionally, using

a filter to create high frequency light assumes that the microscope's bulb

already produces light of that wavelength. I removed the lens on the bulb on the

AmScope microscope, and its tungsten filament bulb worked. The Zenith school

microscopes did not work so well.

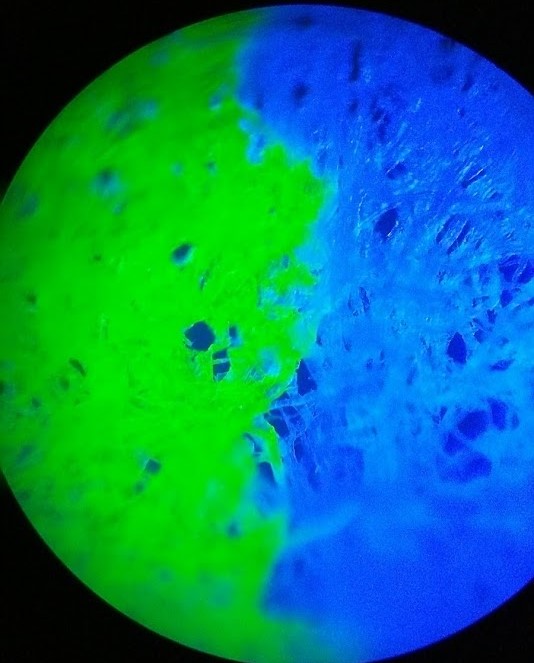

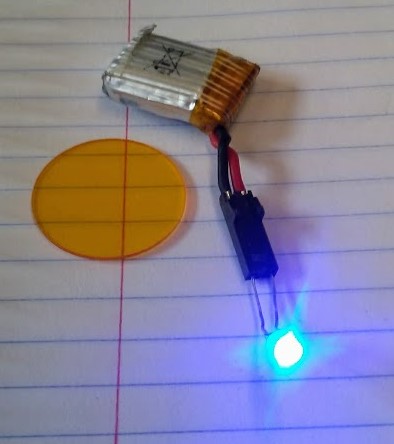

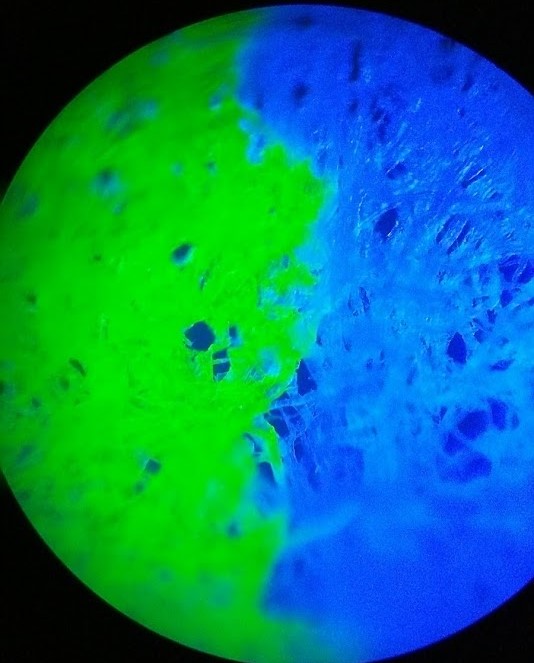

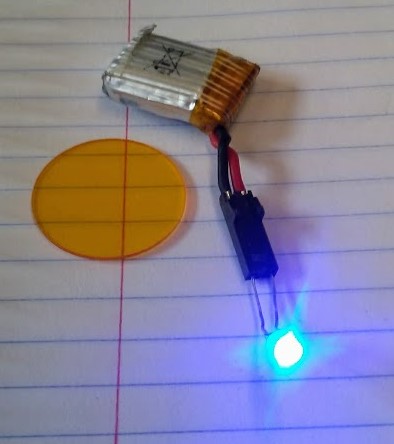

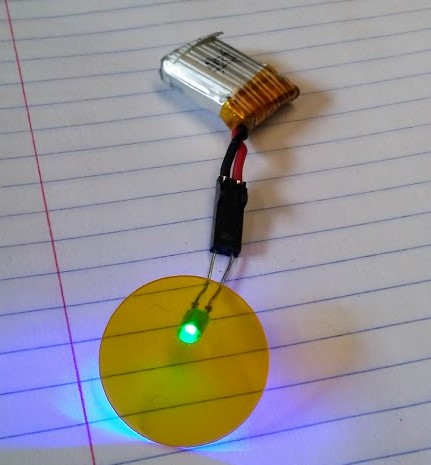

With this in mind, I purchased an LED

from Mouser ELectronics with a wavelength of 475 nm, selected to be the highest

wavelength that could (theoretically) excite GFP. I also purchased a 510nm

longpass filter from

Knight Optical. The acrylic filter itself was only six Euro, but with

shipping, handling and tax, I ended up being charges almost $30. With that

in mind, the filter was removed from consideration as a possible component

in the final solution, but it would still be useful for comparison.

The filter significantly decreases the brightness of the LED, and the datasheet

indicates that very nearly 100% of light under 500nm is blocked out, so

the remaining light should all be a result of a wider wavelength range coming

from the LED.

The filter significantly decreases the brightness of the LED, and the datasheet

indicates that very nearly 100% of light under 500nm is blocked out, so

the remaining light should all be a result of a wider wavelength range coming

from the LED.

The led did create more contrast (using a different sample, obviously),

but light pollution (if you will) from the LED that was not blocked by the

filter made the sample hard to look at. Using a darkfield occulting disk

in conjunction with the LED did a lot to solve this problem.

The led did create more contrast (using a different sample, obviously),

but light pollution (if you will) from the LED that was not blocked by the

filter made the sample hard to look at. Using a darkfield occulting disk

in conjunction with the LED did a lot to solve this problem.

This modification works even without the lense, depending on the sample.

More work will be done to create cheaper and more effective longpass filters,

ideally with adjustable thresholds for use with different indicators. It is

important to note that this microscope only works in the dark, or with a

towel or jacket wrapped around the stage and objective lenses.

This modification works even without the lense, depending on the sample.

More work will be done to create cheaper and more effective longpass filters,

ideally with adjustable thresholds for use with different indicators. It is

important to note that this microscope only works in the dark, or with a

towel or jacket wrapped around the stage and objective lenses.

I have not limited myself to optical microscopes. After trying (and failing)

to find instructions online for building a scanning electron microscope, I

stumbled upon Dan Berard's STM. Dan Berard

had taken a concept originally described by John Alexander and developed

a functional and refined STM using a piezo element. I would highly recommend

Dan Berard's website for nayone who is interested in this project, his

descriptions are incredibly clear and he has made available everything you

need to create your own. So that is exactly what I did.

At the heart of the STM is a piezo amplifier. They are used to build impact

sensors and guitar amplifiers and they are extremely cheap: I purchased this

bag of 20 on ebay for only $3. The thin white layer on the piezo disk is

piezoelectric ceramic, which flexes when electricity is passed through it.

John Alexander showed that by cutting the ceramic into four quarters, the

disk could be made to flex in a specific way.

At the heart of the STM is a piezo amplifier. They are used to build impact

sensors and guitar amplifiers and they are extremely cheap: I purchased this

bag of 20 on ebay for only $3. The thin white layer on the piezo disk is

piezoelectric ceramic, which flexes when electricity is passed through it.

John Alexander showed that by cutting the ceramic into four quarters, the

disk could be made to flex in a specific way.

An atomically-sharp tip is made by shattering tungsten wire with a set

of wire cutters, and then mounted on the center of the piezo disk. An

oscilloscope sends a sine wave to the piezo scanner, which moves back and

forth, and the current flowing from the tip to the sample surface is

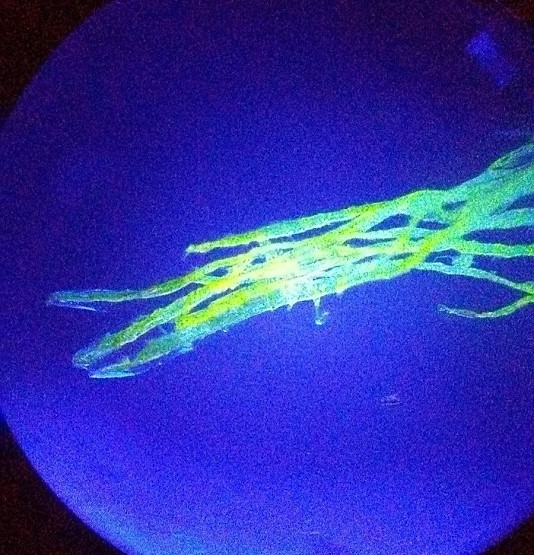

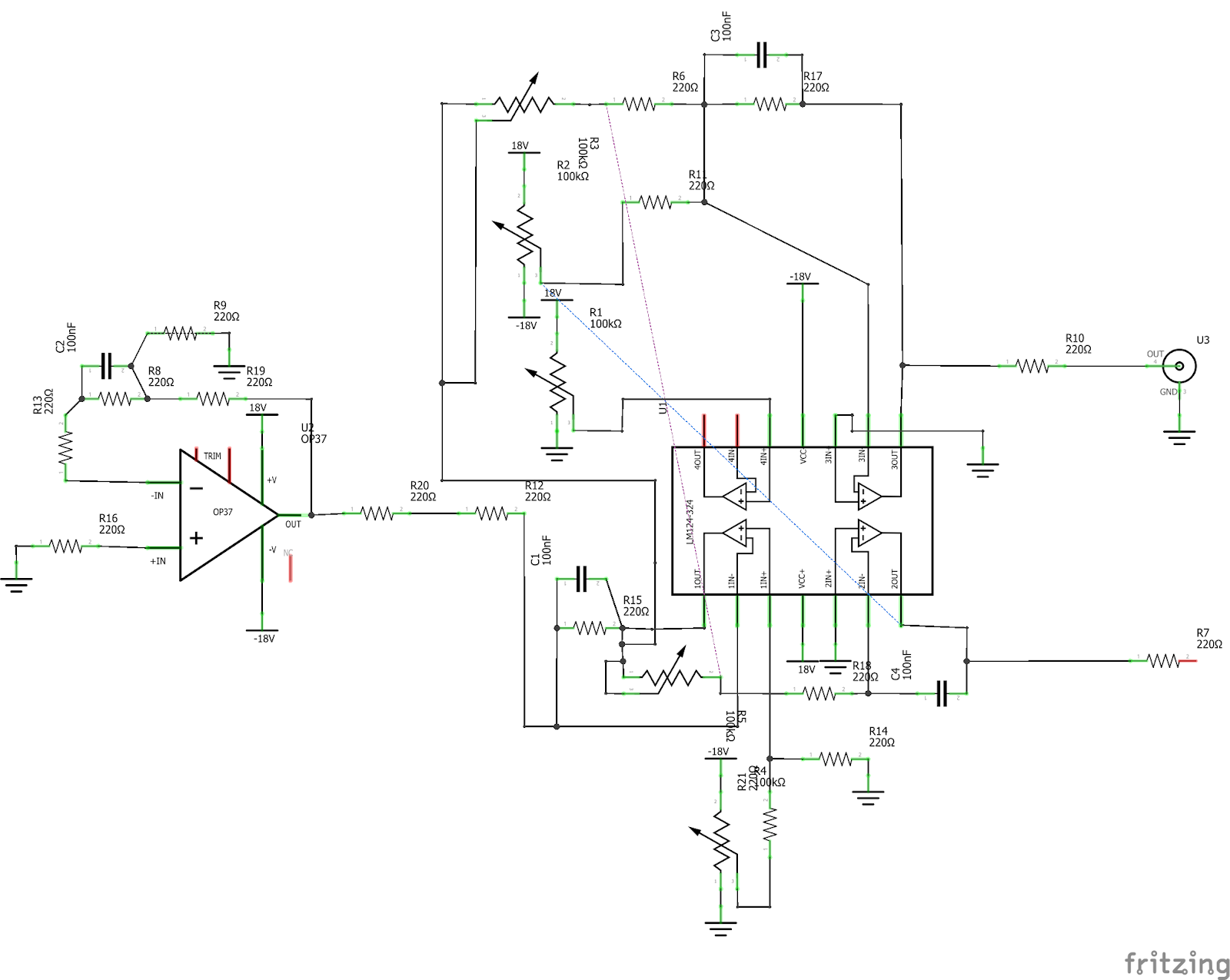

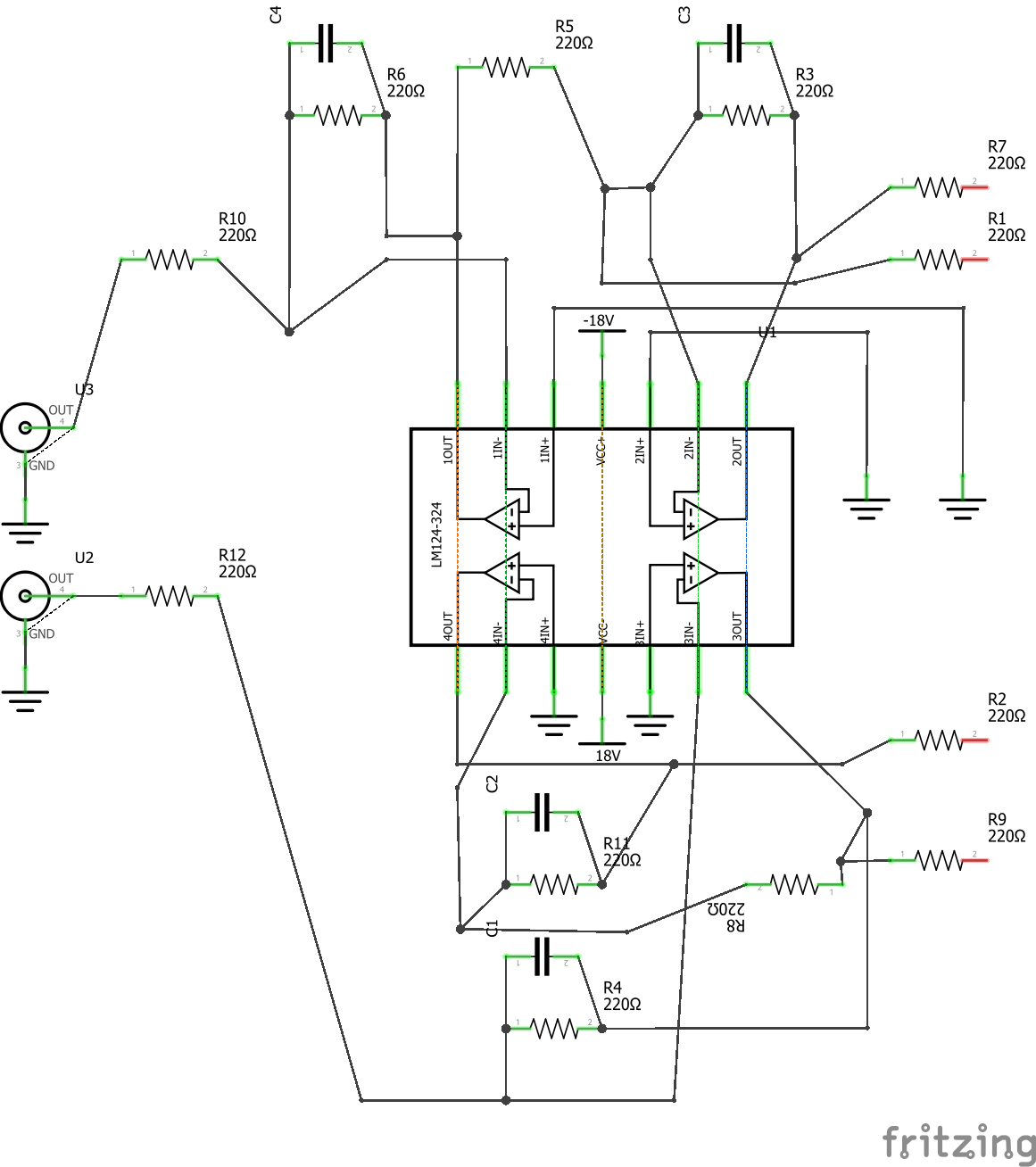

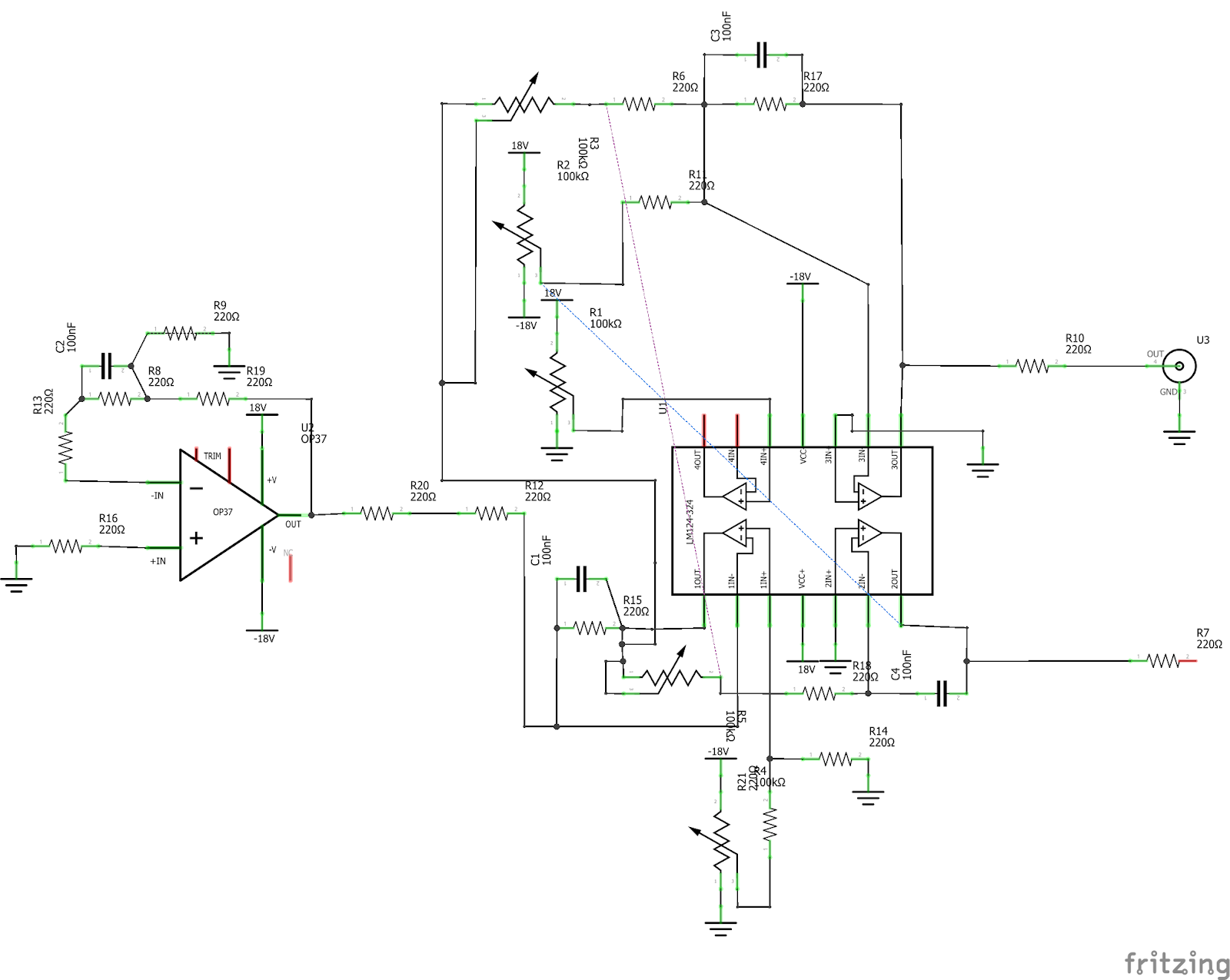

amplified and measured, which creates an image. I used John Alexander's

amplifier circuit because it is simpler, albeit less refined, and remade the

circuit on Fritzing to prepare it for breadboarding (yep, I did that).

An atomically-sharp tip is made by shattering tungsten wire with a set

of wire cutters, and then mounted on the center of the piezo disk. An

oscilloscope sends a sine wave to the piezo scanner, which moves back and

forth, and the current flowing from the tip to the sample surface is

amplified and measured, which creates an image. I used John Alexander's

amplifier circuit because it is simpler, albeit less refined, and remade the

circuit on Fritzing to prepare it for breadboarding (yep, I did that).

These are my adaptations of John Alexanders XY Controller (top) and amplifier

(bottom) circuits, done in Fritzing. These schematics are ideantical to those

published on Alexander's Website,

but re-creating them in Fritzing allowed me to manipulate them and alter the

layout. I ordered the parts from Mouser Electronics, and started designing

the mechanics of the STM.

These are my adaptations of John Alexanders XY Controller (top) and amplifier

(bottom) circuits, done in Fritzing. These schematics are ideantical to those

published on Alexander's Website,

but re-creating them in Fritzing allowed me to manipulate them and alter the

layout. I ordered the parts from Mouser Electronics, and started designing

the mechanics of the STM.

This is what I put together in FreeCAD:

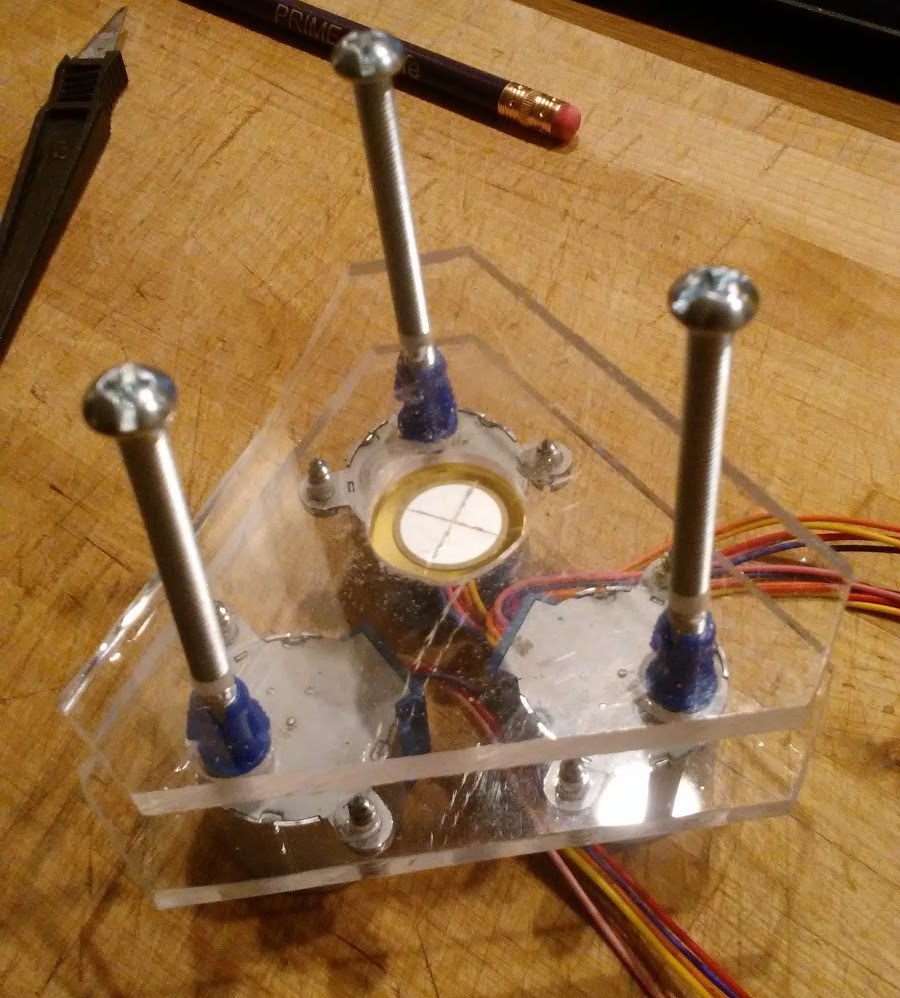

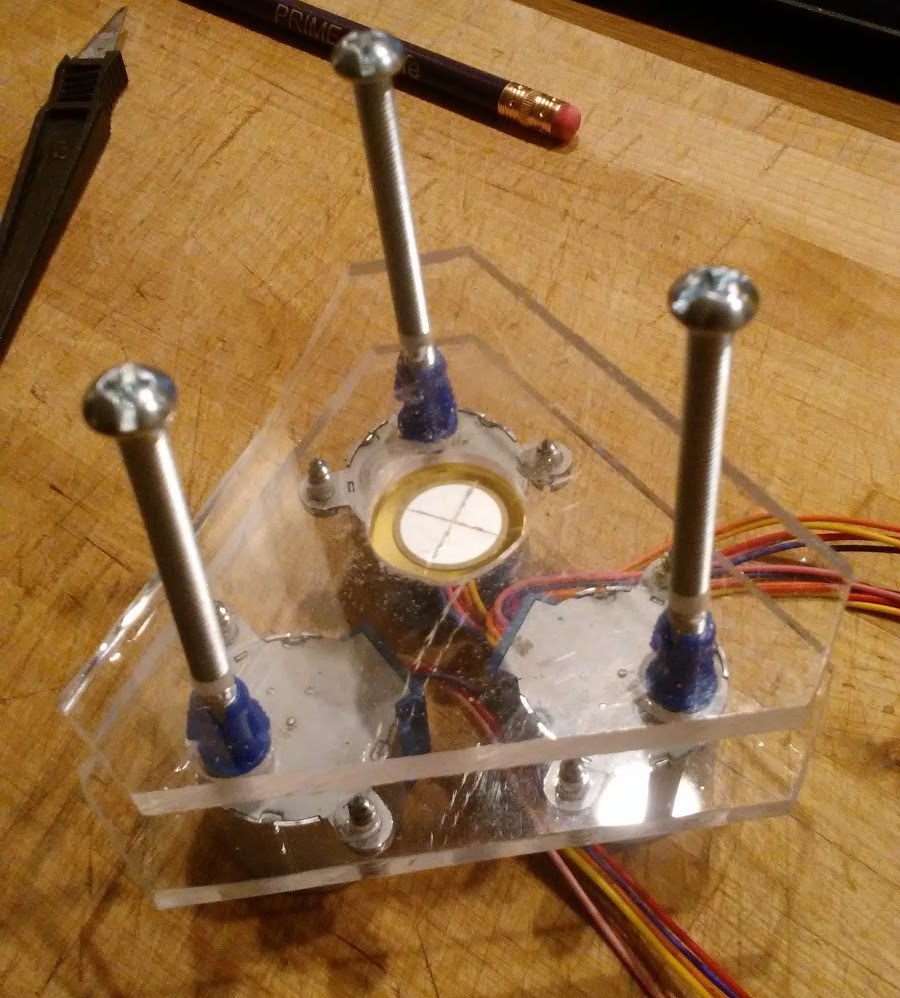

Everything about this design is inspired by Dan Berard's STM, with acrylic

plates for vibration isolation and three BYJ-48 stepper motors instead of

one for full range of motion. The STEP file for this design is available

here.

Everything about this design is inspired by Dan Berard's STM, with acrylic

plates for vibration isolation and three BYJ-48 stepper motors instead of

one for full range of motion. The STEP file for this design is available

here.

I learned then that cutting acrylic without a laser cutter (a convienience

I had yet to have access to) is hard. The top and bottom plates were

not straight, but the edges did not matter as long as the holes were all

aligned. I had more difficulty mounting the stepper motors to the acrylic,

because the screws would fracture the plastic as I inserted them. Here is the

final STM:

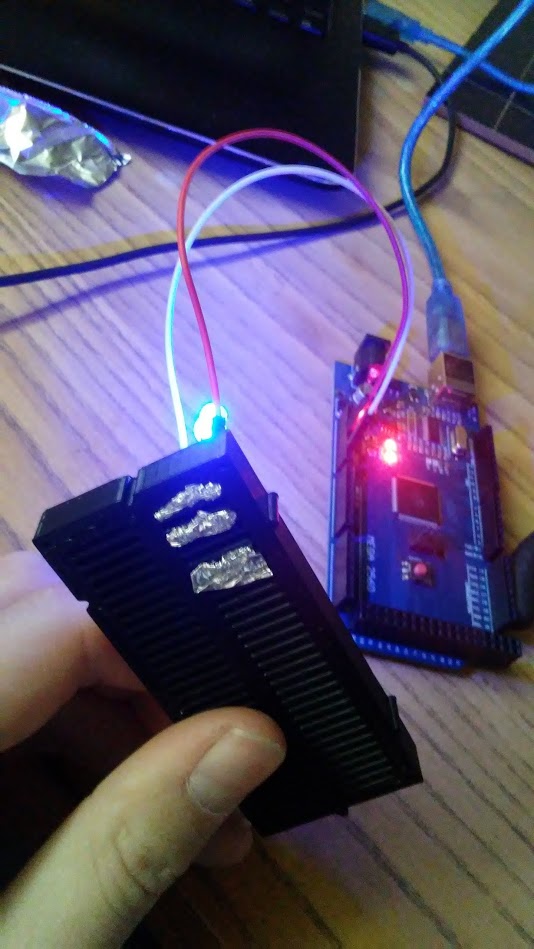

To further isolate vibrations, I used sections cut from three drywall anchors

to couple the stepper motors to the actuators. Now it was time for electronics:

To further isolate vibrations, I used sections cut from three drywall anchors

to couple the stepper motors to the actuators. Now it was time for electronics:

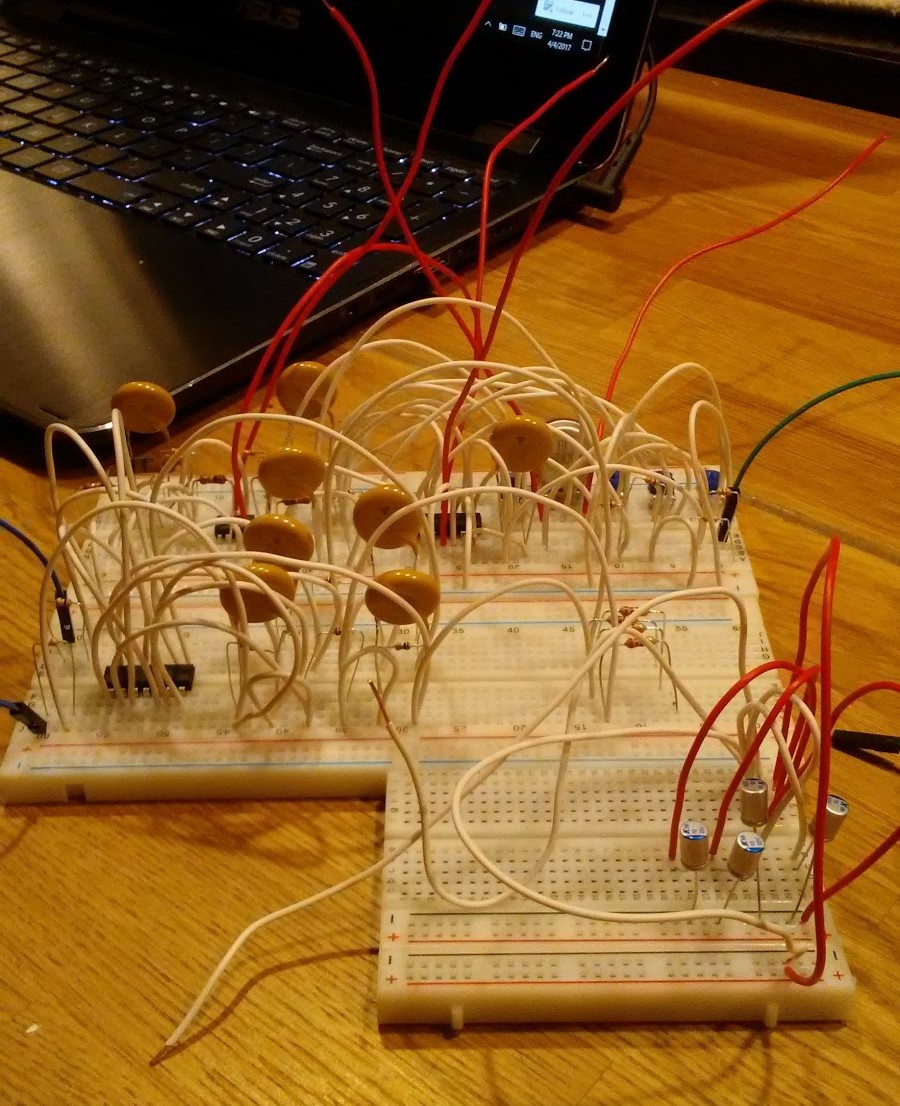

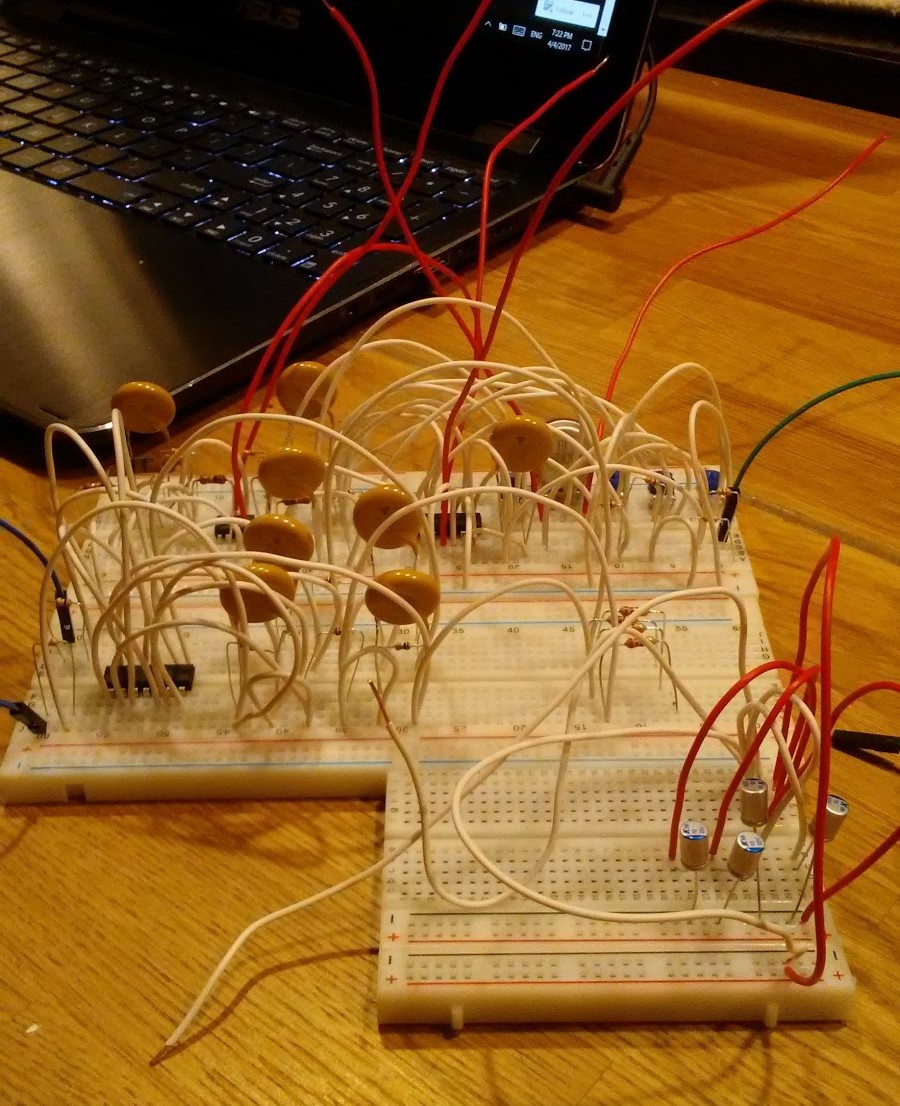

A relatively simple circuit became incredibly hard to manage when built on

a breadboard. After hours of finding problems and adjusting component positions,

I finally recieved a signal. I combined the electronics with the mechanical

components, and I was ready to run my first test.

A relatively simple circuit became incredibly hard to manage when built on

a breadboard. After hours of finding problems and adjusting component positions,

I finally recieved a signal. I combined the electronics with the mechanical

components, and I was ready to run my first test.

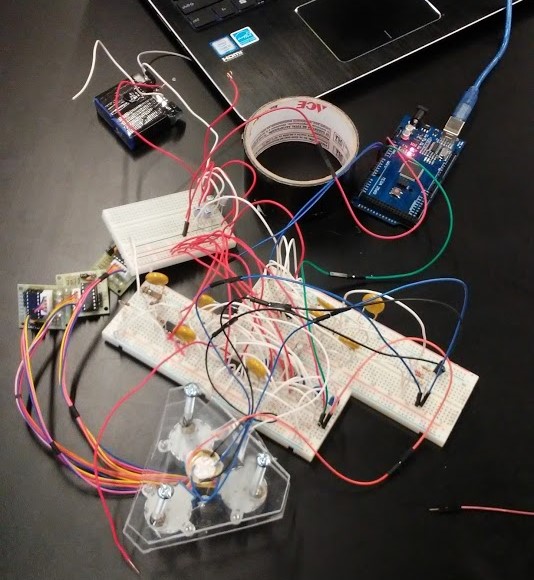

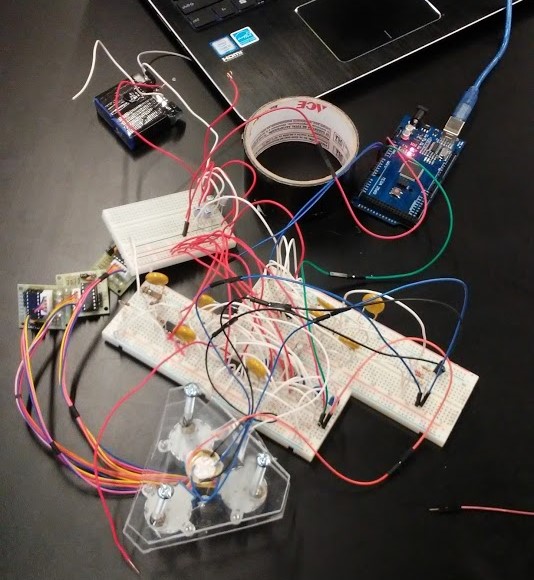

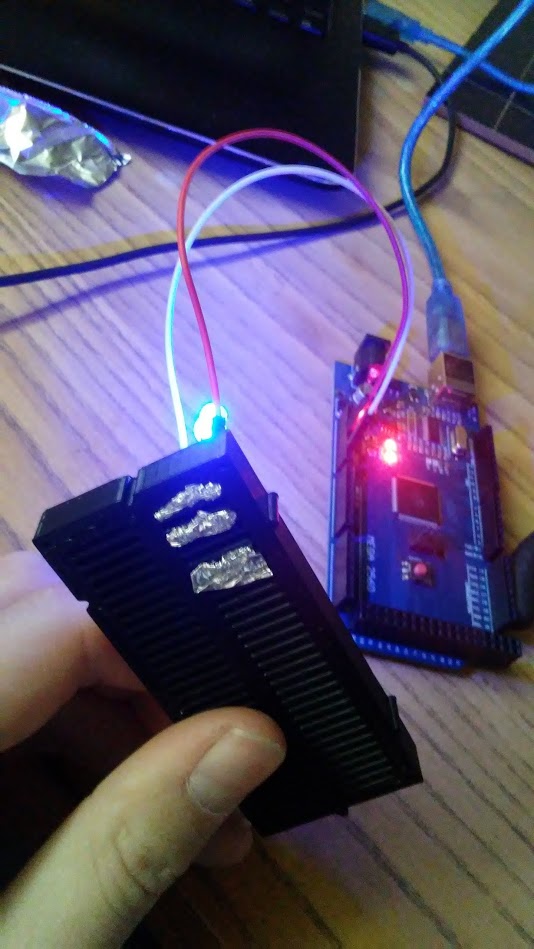

The Arduino Mega acted as the oscilloscope required to send a signal to the

probe, while an Arduino Uno measured the signal from the amplifier circuit.

A script written in Processing showed the oscilloscope readings on my computer

screen. The BYJ-48 Happy Drivers are disconnected after homing to prevent

wobble, an idea suggested by Dan Berard.

The Arduino Mega acted as the oscilloscope required to send a signal to the

probe, while an Arduino Uno measured the signal from the amplifier circuit.

A script written in Processing showed the oscilloscope readings on my computer

screen. The BYJ-48 Happy Drivers are disconnected after homing to prevent

wobble, an idea suggested by Dan Berard.

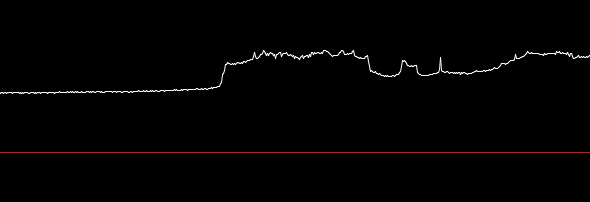

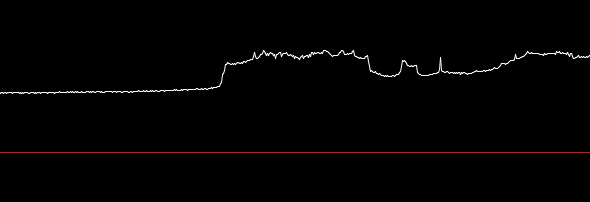

These readings are the closest that my STM got to being operational:

The first image shows the readings when power is first sent to the STM,

after which it begins scanning. The second shows the reading I received

after accidentally crashing the tip into the sample (a piece of flattened

copper wire). It is quite likely that these readings are entirely insignificant,

or merely due to static.

The first image shows the readings when power is first sent to the STM,

after which it begins scanning. The second shows the reading I received

after accidentally crashing the tip into the sample (a piece of flattened

copper wire). It is quite likely that these readings are entirely insignificant,

or merely due to static.

I have since scrapped the STM for its components, but I really would like

to try the project again, armed with a better understanding of electronics

and the ability to make PCBs, which would help with debugging and analysis.

Kites/Drones

Kites are really simple and really fun. Very little beats being outside on

a windy day with a kite... except maybe FPV kites.

After being frustrated by the short duration of FPV drone flights, flying

a kite seems almost too good to be true, especially when you have two

people. The only difficulty is in positioning the camera so that it does

not flap in the wind. The first step is building a kite.

The parts for the kite include a few sticks (I had three carbon fiber

tubes laying around, but they certainly aren't necessary), a trash bag,

some tape, string, and three sheets of paper. Tape the sticks together to

form a diamond, and cut open the trash bag.

The parts for the kite include a few sticks (I had three carbon fiber

tubes laying around, but they certainly aren't necessary), a trash bag,

some tape, string, and three sheets of paper. Tape the sticks together to

form a diamond, and cut open the trash bag.

Cut the trash bag to fit around the cross, and attach a length of string

to the cross spar.

Cut the trash bag to fit around the cross, and attach a length of string

to the cross spar.

A piece of tape on the inside of the string keeps it from falling inward.

To create a streamer, remove the drawstring from the bag (you might have

to cut it in half), and tape it to the bottom of the kite. Cut a sheet

of paper in half, and crumple the middle until it forms a bow. Repeat

these steps until you have six bows, then tape these to the streamer. The

kite is ready to fly!

A piece of tape on the inside of the string keeps it from falling inward.

To create a streamer, remove the drawstring from the bag (you might have

to cut it in half), and tape it to the bottom of the kite. Cut a sheet

of paper in half, and crumple the middle until it forms a bow. Repeat

these steps until you have six bows, then tape these to the streamer. The

kite is ready to fly!

The FPV setup is also incredibly simple. I 3D printed a set of VR goggles

from Kuutio3D on Thingiverse,

and set up a 5.8 MHz reciever for a cheap FPV camera. I crimped header pins

onto a battery and onto the leads on the camera, so they can be clipped

together easily.

The FPV setup is also incredibly simple. I 3D printed a set of VR goggles

from Kuutio3D on Thingiverse,

and set up a 5.8 MHz reciever for a cheap FPV camera. I crimped header pins

onto a battery and onto the leads on the camera, so they can be clipped

together easily.

The camera was the cheapest I could find on the internet, so the images

aren't great, but they are still pretty entertaining:

The camera was the cheapest I could find on the internet, so the images

aren't great, but they are still pretty entertaining:

Of course, it is nice to have control over your direction, and for that,

we have drones. Due to the popularity of drone piloting, building and

flying all kinds of drones is pretty straightforeward. My best-documented

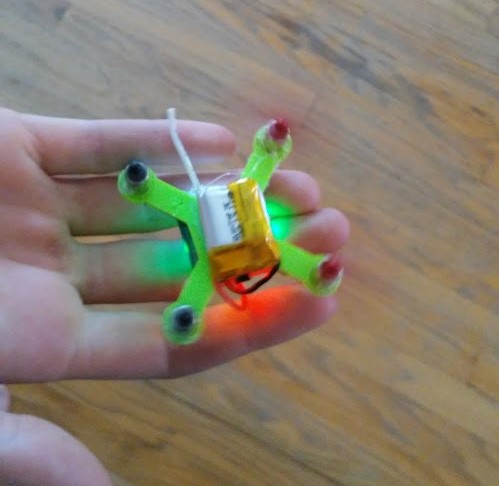

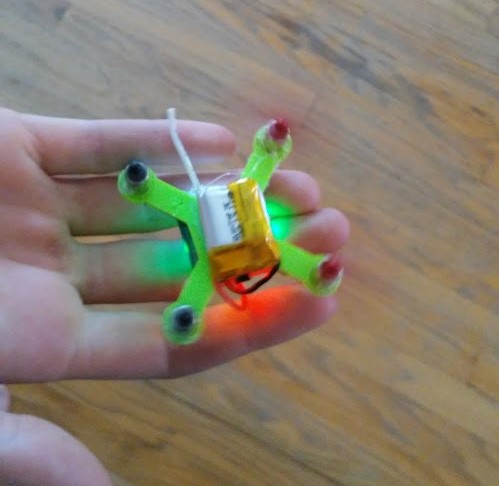

drone project was for an engineering class in 2017.

Of course, it is nice to have control over your direction, and for that,

we have drones. Due to the popularity of drone piloting, building and

flying all kinds of drones is pretty straightforeward. My best-documented

drone project was for an engineering class in 2017.

This drone was built from parts scavenged from other drones, fit into

a body that was stress tested and designed for weight. The body was

designed in an educational version of Autodesk Inventor Professional

CAD software.

This drone was built from parts scavenged from other drones, fit into

a body that was stress tested and designed for weight. The body was

designed in an educational version of Autodesk Inventor Professional

CAD software.

After 3D printing, each of the parts snapped in, the battery was glued on

top, and the drone flew!

After 3D printing, each of the parts snapped in, the battery was glued on

top, and the drone flew!

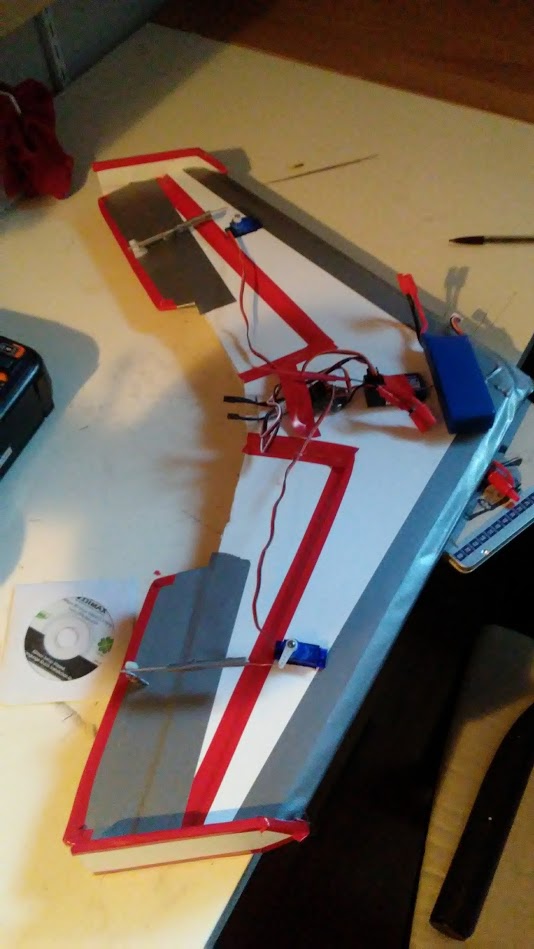

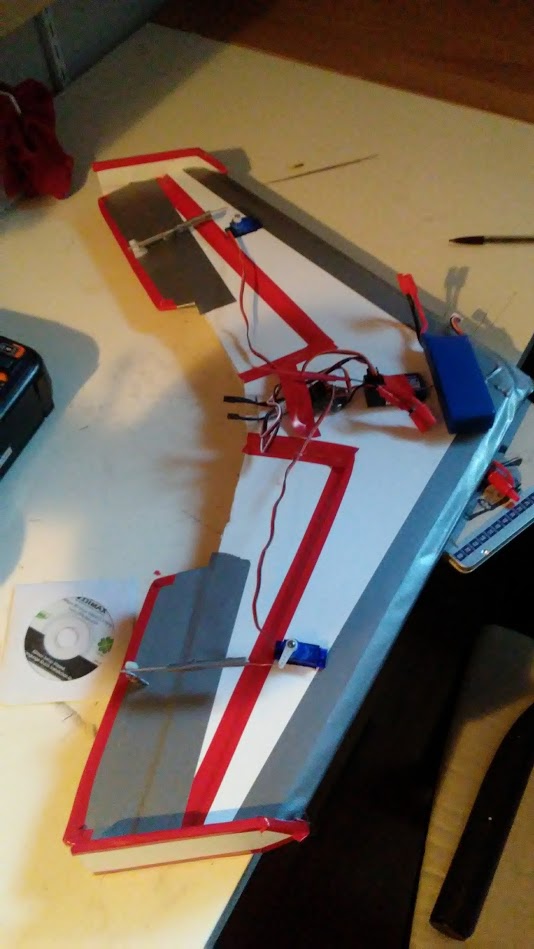

Recently, I became more interested in building rc planes instead of quadcopters

because of greater efficiency and load capacity. I don't have pictures of all

the builds, but here are each of the finished planes (not all of which flew).

Recently, I became more interested in building rc planes instead of quadcopters

because of greater efficiency and load capacity. I don't have pictures of all

the builds, but here are each of the finished planes (not all of which flew).

It's pretty obvious why this plane didn't fly. The enormous battery on the

nose threw it into a dive within a few seconds of launch every time.

It's pretty obvious why this plane didn't fly. The enormous battery on the

nose threw it into a dive within a few seconds of launch every time.

After my failure with the first flying wing, I decided to go back to the

basics. My friend and I built the Flite Test Tiny Trainer.

This plane glided beautifully, but we did not have a programmable electronic

speed controller, so we did not put a motor on it. We still have the plane,

and the only thing preventing us from flying it is time.

After my failure with the first flying wing, I decided to go back to the

basics. My friend and I built the Flite Test Tiny Trainer.

This plane glided beautifully, but we did not have a programmable electronic

speed controller, so we did not put a motor on it. We still have the plane,

and the only thing preventing us from flying it is time.

This was the ultimate glider project. Designed after the Horton H IV, this

glider was built out of choroplast for stiffness and waterproofing, and

could support a pushed propeller as well. The plan is to tow this plane

behind a kite, then release it with a servo and fly it to the ground using a

remote control.

This was the ultimate glider project. Designed after the Horton H IV, this

glider was built out of choroplast for stiffness and waterproofing, and

could support a pushed propeller as well. The plan is to tow this plane

behind a kite, then release it with a servo and fly it to the ground using a

remote control.

The glider is built with a steep airfoil and dihedral wings for stability at

low speeds, and uses only three channels. Like the flying wing, the elevator

and aileron functions are combined using a V-Tail mixer.

The glider is built with a steep airfoil and dihedral wings for stability at

low speeds, and uses only three channels. Like the flying wing, the elevator

and aileron functions are combined using a V-Tail mixer.

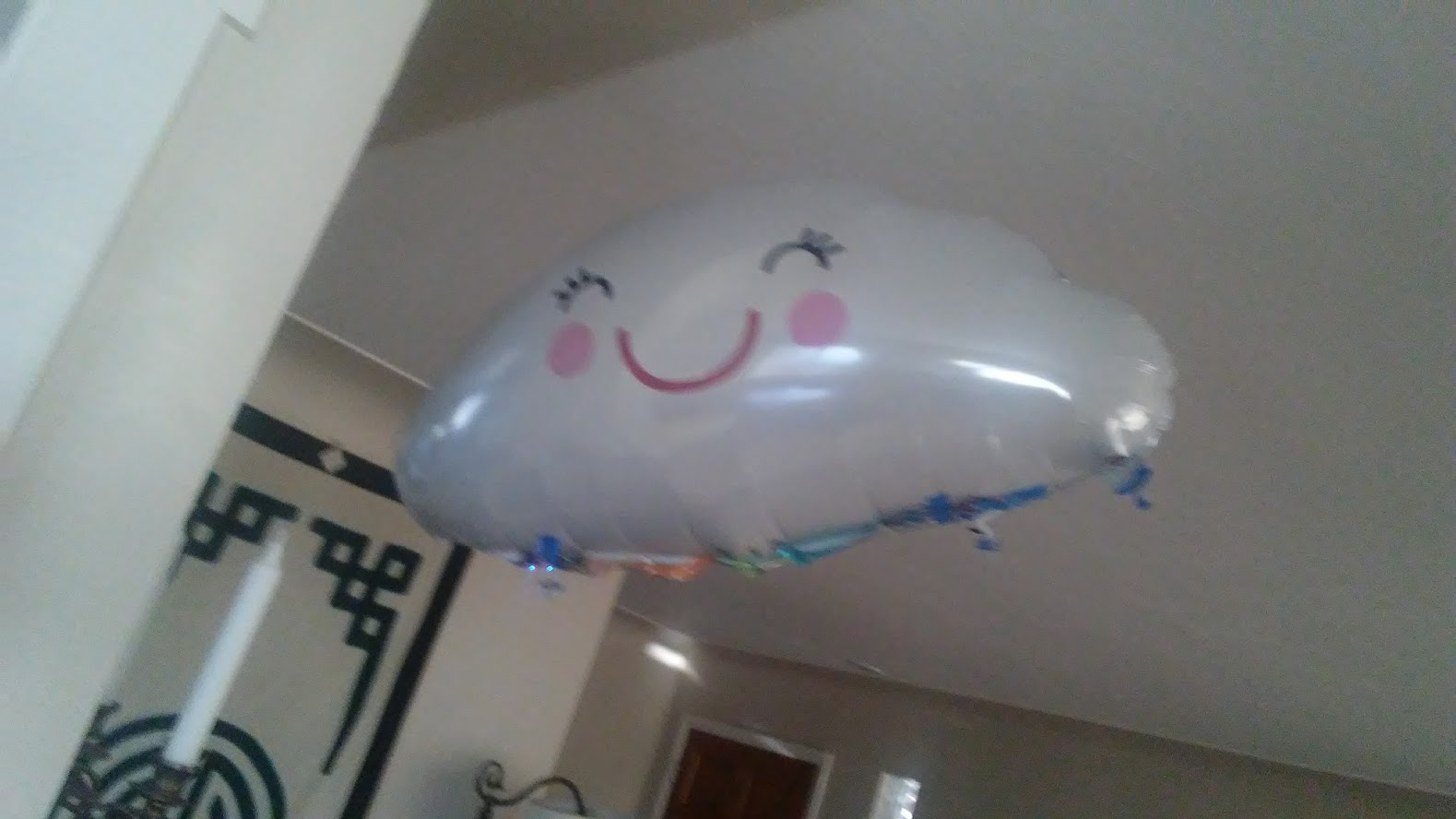

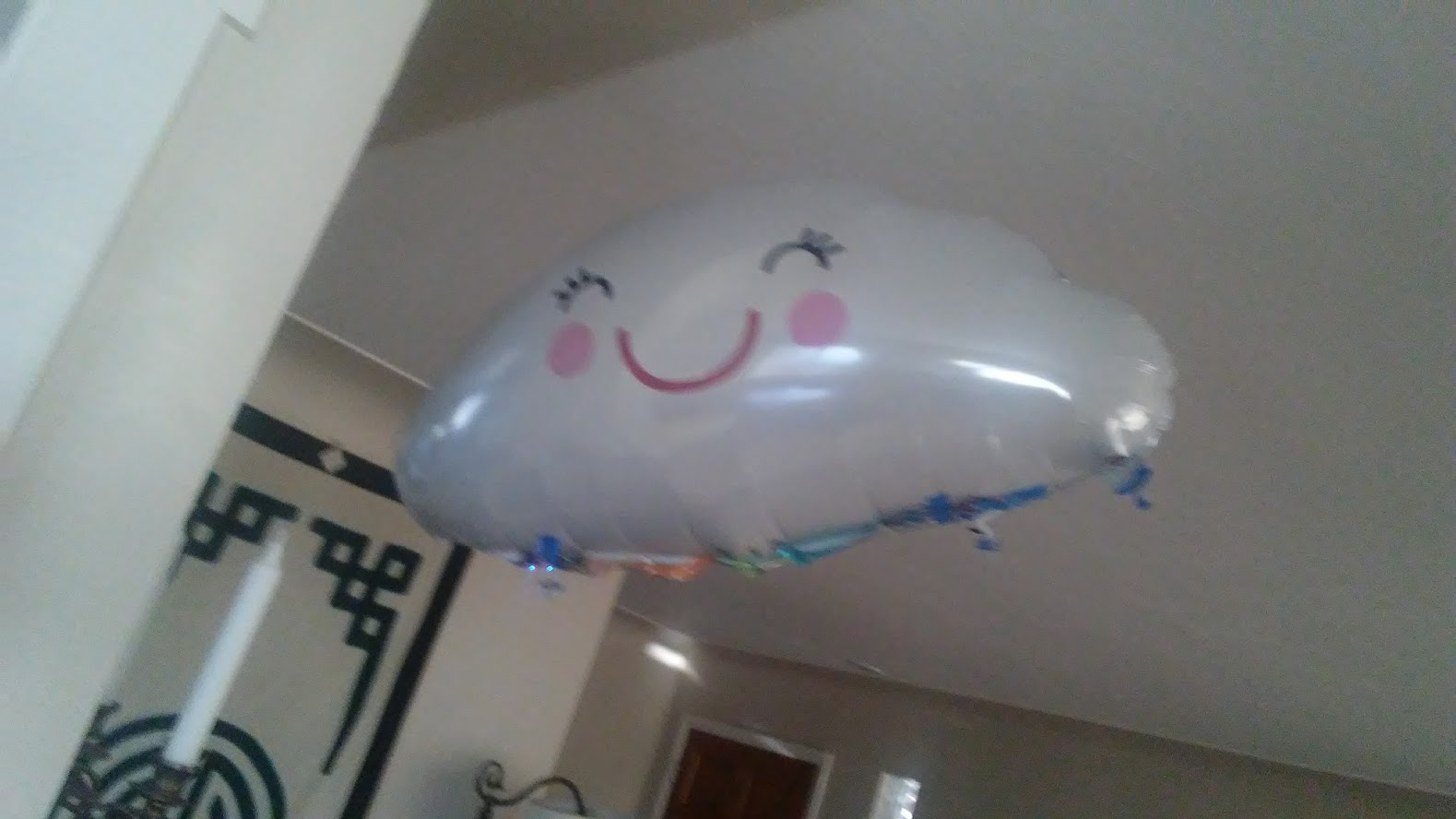

Finally, setting all elegance aside, there are blimps. This project is more

silly than useful or cool, but in retrospect it was one of the most fun things

I've built all year.

This project was done with my sister on a weekend with nothing else to do. We

removed the electronics from a cheap 2 channel RC car, and replaced the

electromagnet used for steering with a small dc motor from a drone. We fixed

propellers onto each of the motors' shafts, and attached them, at right angles,

to the bottom of a helium balloon we bought at a grocery store. By adding coins,

we could make the balloon slightly less than neutrally bouyant, and by angling the

propeller downward, we could control both the height and the foreward

velocity of the balloon simultaneously. The othe rmotor was used for steering.

This project was done with my sister on a weekend with nothing else to do. We

removed the electronics from a cheap 2 channel RC car, and replaced the

electromagnet used for steering with a small dc motor from a drone. We fixed

propellers onto each of the motors' shafts, and attached them, at right angles,

to the bottom of a helium balloon we bought at a grocery store. By adding coins,

we could make the balloon slightly less than neutrally bouyant, and by angling the

propeller downward, we could control both the height and the foreward

velocity of the balloon simultaneously. The othe rmotor was used for steering.

The blimp flew remarkably well. The incredibly slow speed and low risks

involved with collisions meant that it was not as difficult to fly as one

might expect (untill all of the helium leaked out of the mylar).

The blimp flew remarkably well. The incredibly slow speed and low risks

involved with collisions meant that it was not as difficult to fly as one

might expect (untill all of the helium leaked out of the mylar).

Rocket Engines

This was probably the most entertaining project I have worked on recently.

A series of discussions with my chemistry teacher about the role of iron

oxide in dry rocket fuels demanded experimentation, and after researching

rocket candy online, I realized that it would be very possible to create

solid fuel rocket engines without any expensive materials or special equipment.

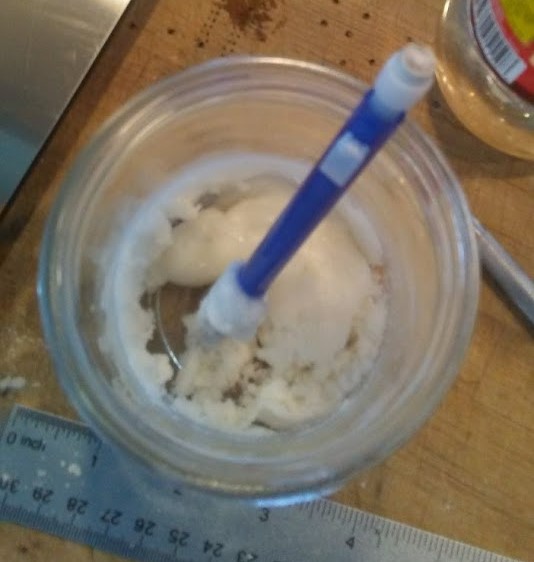

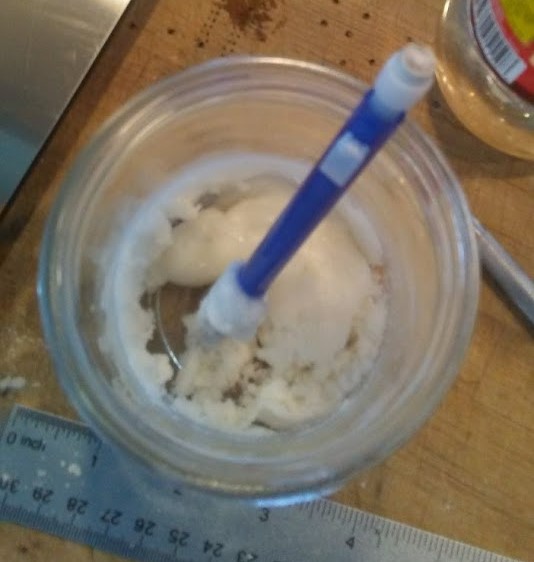

These are the only things you need to make rocket candy, in fact, you could

probably get away with just the potassium nitrate and sugar. The postassium

nitrate is a strong oxidizing agent: when it is added to the sugar (which

would burn slowly anyway) it speeds up the reaction to the point where

the exhaust gasses produce meaningful thrust.

These are the only things you need to make rocket candy, in fact, you could

probably get away with just the potassium nitrate and sugar. The postassium

nitrate is a strong oxidizing agent: when it is added to the sugar (which

would burn slowly anyway) it speeds up the reaction to the point where

the exhaust gasses produce meaningful thrust.

In my recipe, corn syrup is used as a binder until the melted sugar is added,

which results in a pretty gooey mixture until it dries. It is also very

popular to add Iron Oxide, presumably as a catalyst, to increase thrust

and burn rate.

I started by making a bunch of paper mache tubes for the motors, each with

a capacity of 5ml. This proved to be a mistake, because the tiny surface

area of the fuel column caused an extremely slow burn rate.

I started by making a bunch of paper mache tubes for the motors, each with

a capacity of 5ml. This proved to be a mistake, because the tiny surface

area of the fuel column caused an extremely slow burn rate.

As it turns out, black iron oxide is the key ingredient in a lot of toners,

which explains the inky black color. After adding the melted sugar (outside,

wearing PPE and with a fire extinguisher handy), it was time to fill the

tubes with rocket fuel.

As it turns out, black iron oxide is the key ingredient in a lot of toners,

which explains the inky black color. After adding the melted sugar (outside,

wearing PPE and with a fire extinguisher handy), it was time to fill the

tubes with rocket fuel.

This was not as easy as I thought it would be. As the sugar cooled, the

fuel became hard and chunky, so it was difficult to pack into the tiny

tubes. Additionally, the fuel was extremely sticky and it would stain anything

it came into contact with.

This was not as easy as I thought it would be. As the sugar cooled, the

fuel became hard and chunky, so it was difficult to pack into the tiny

tubes. Additionally, the fuel was extremely sticky and it would stain anything

it came into contact with.

When all the fuel was packed into tubes, I wrapped them in one more sheet

of blank paper, and they were ready for testing.

When all the fuel was packed into tubes, I wrapped them in one more sheet

of blank paper, and they were ready for testing.

It is illegal to launch a rocket with a custom motor (like the ones I built)

in the United States without a liscence, which I am inelligible for because

I am not yet 18. It is not illegal, however, to burn these motors on the ground,

so I built a small mount using a few bricks and tested them in my backyard.

It is illegal to launch a rocket with a custom motor (like the ones I built)

in the United States without a liscence, which I am inelligible for because

I am not yet 18. It is not illegal, however, to burn these motors on the ground,

so I built a small mount using a few bricks and tested them in my backyard.

As you can see, the motors did not produce spectacular plumes of exhaust.

This is a consequence of two things: first, the rediculously small amount

of fuel in a long tube yielded a long burn time with very little thrust.

Additionally, the paper mache tubes were not completely dry, so they did

not burn away as they should have.

As you can see, the motors did not produce spectacular plumes of exhaust.

This is a consequence of two things: first, the rediculously small amount

of fuel in a long tube yielded a long burn time with very little thrust.

Additionally, the paper mache tubes were not completely dry, so they did

not burn away as they should have.

I will be rebuilding these engines with different amounts of FeO and Fe2O3,

with a larger surface area and thinner tubes.

Biofuel (Pyrolysis)

Returning to the "money or science" solutions to global warming, what

better way to prevent greenhouse gasses than by synthesizing oil? During

WWII, the British used "syngas" to fuel cars and tractors, and it amazed

me to learn that we have been capable of producing oil from complex hydrocarbons

for decades, and yet no one was working on producing refined gasses (like

petroleum) from waste biomass.

In an attempt to better understand the hurdles we were facing, I decided

to build a pyrolysis reactor. The principle of operation is that heat and

pressure cause longer hydrocarbons to break down. Lower London dispersion

forces in these molecules means a lower boiling point, and when they

reach the appropriate size, they flow up through a condenser and drip

into a container.

My reactor was built from a bucket with a refrigeration coil flare-fitted

to the lid. This provided an airtight reaction chamber that could be easily

opened and inspected, although soldering the flare fitting to the lid of

the paint can was not easy. I ran the refrigeration coil through a bucket

of water to enhance cooling, but removed it later because condensed

gas in the coil in the bucket caused a rise in pressure in the container.

My reactor was built from a bucket with a refrigeration coil flare-fitted

to the lid. This provided an airtight reaction chamber that could be easily

opened and inspected, although soldering the flare fitting to the lid of

the paint can was not easy. I ran the refrigeration coil through a bucket

of water to enhance cooling, but removed it later because condensed

gas in the coil in the bucket caused a rise in pressure in the container.

I managed to extract about 60ml of gas from a few apple cores, dried leaves

and sticks, and 30ml from scrap PLA from 3D prints. I did not control for

input volume so these numbers do not reflect efficiencies.

I managed to extract about 60ml of gas from a few apple cores, dried leaves

and sticks, and 30ml from scrap PLA from 3D prints. I did not control for

input volume so these numbers do not reflect efficiencies.

I did note a huge difference in color between the PLA and organic matter -

the PLA produced a much clearer oil. This is most likely attributable to the

consistency of the material in the PLA trial, and the PLA had already been

processed. I will work on distilling and refining these samples with my

chemistry teacher.

I did note a huge difference in color between the PLA and organic matter -

the PLA produced a much clearer oil. This is most likely attributable to the

consistency of the material in the PLA trial, and the PLA had already been

processed. I will work on distilling and refining these samples with my

chemistry teacher.

Random/Pictures

I have so many more projects that I neglected to document, or that just

weren't worthy of mention on their own. I've included pictures and brief

descriptions here.

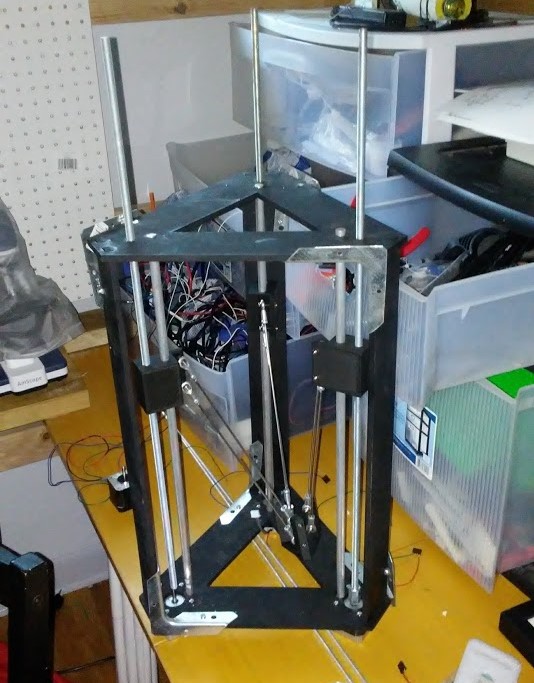

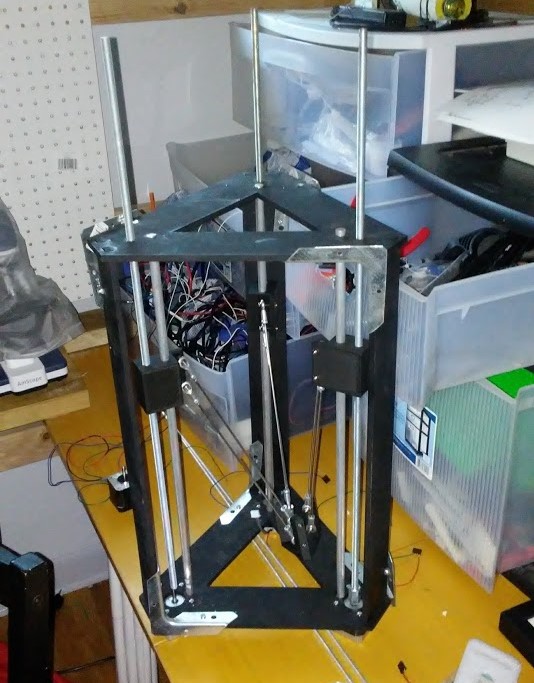

This is a delta 3D printer I designed for my friend, who I was working with

to build a printer capable of printingin aluminum using a MIG welder. We never

bought the welder (turns out they are pretty expensive), so we never used it.

This is a delta 3D printer I designed for my friend, who I was working with

to build a printer capable of printingin aluminum using a MIG welder. We never

bought the welder (turns out they are pretty expensive), so we never used it.

I need a breadboard... why not 3D print one? ...because you need clips.

Tin foil works extremely well until it falls apart.

I need a breadboard... why not 3D print one? ...because you need clips.

Tin foil works extremely well until it falls apart.

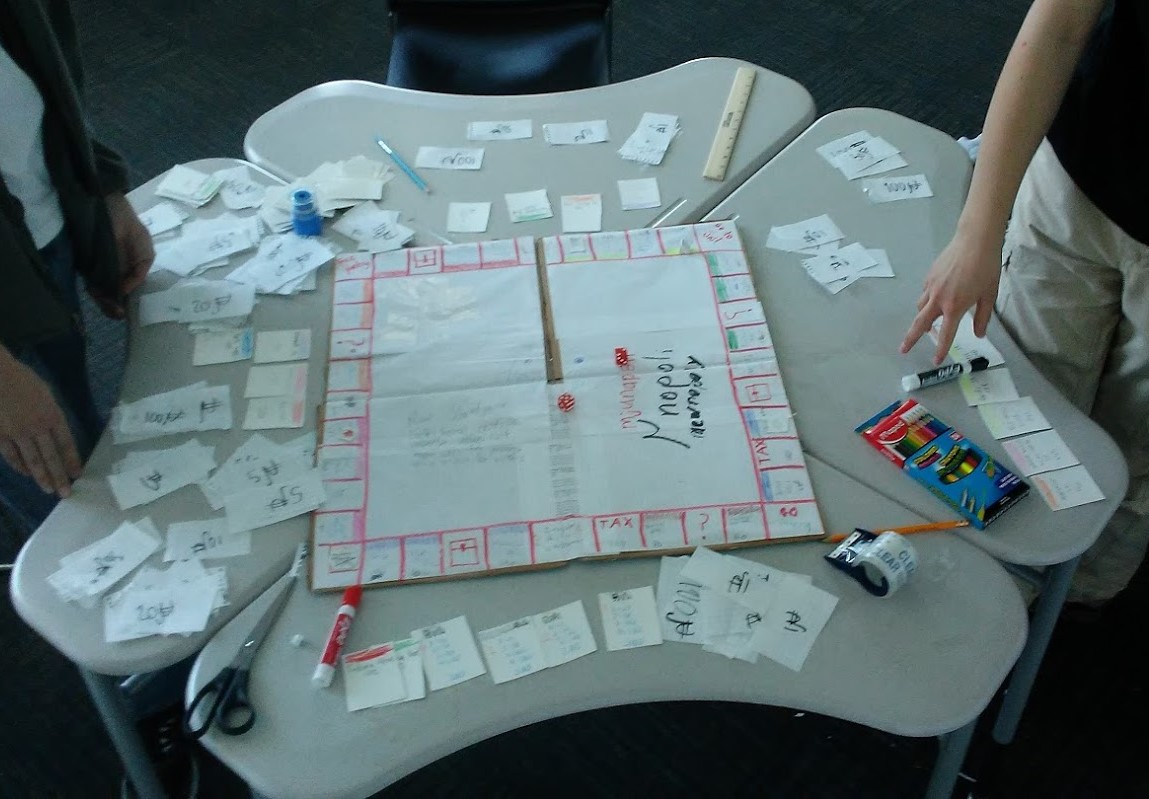

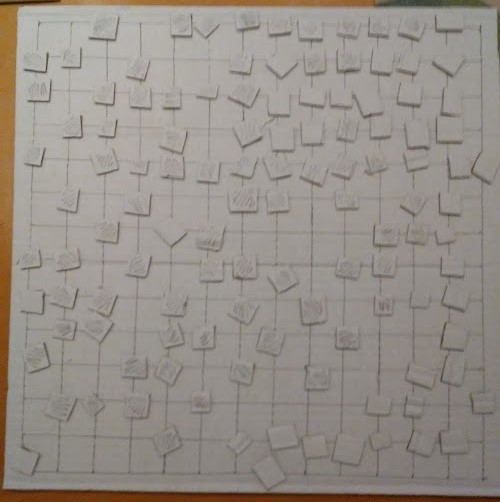

Board games are fun, especially Go and Chess. Unfortunately, it's hard to

keep a set handy at all times (and nice go sets can cost $30), so I've

found myself making my own more often than I'd like to admit. I use the

black Go set all the time; all the lines were made in a scrap of chalkboard

with a eye bolt and a ruler, and the pieces are knots of rope tied by

rope with the ends sealed with a candle.

Board games are fun, especially Go and Chess. Unfortunately, it's hard to

keep a set handy at all times (and nice go sets can cost $30), so I've

found myself making my own more often than I'd like to admit. I use the

black Go set all the time; all the lines were made in a scrap of chalkboard

with a eye bolt and a ruler, and the pieces are knots of rope tied by

rope with the ends sealed with a candle.

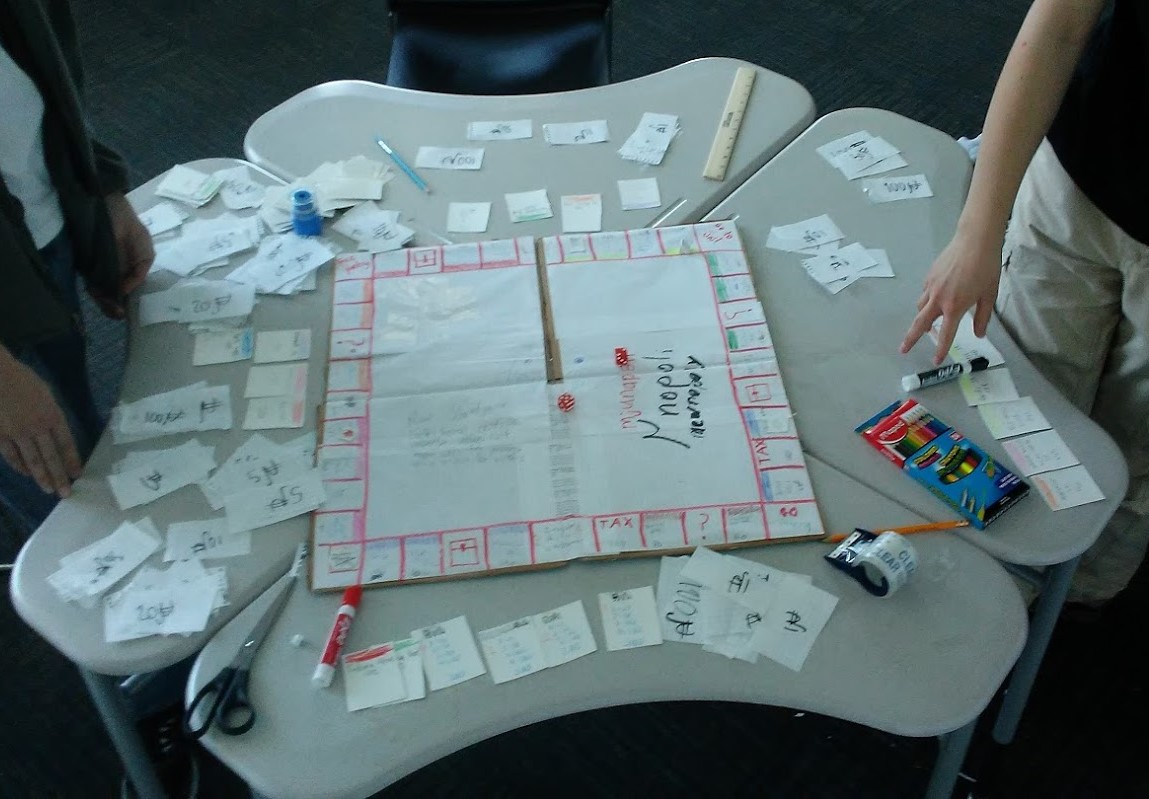

This project was so much fun! My friend and I decided we were bored with

3D printing and wanted something slightly more dangerous, so we went to

Home Depot and bought 2' by 4' sheet of 3/5" MDF, and built a CNC machine.

At the time, however, neither of us were old enough to drive, so we had to

tie the MDF to my bike, and run it back to his house. The CNC machine

worked, but we were both hired by Mindcraft Makerspace within the month

and the laser cutters there made our CNC machine pale in comparison.

This project was so much fun! My friend and I decided we were bored with

3D printing and wanted something slightly more dangerous, so we went to

Home Depot and bought 2' by 4' sheet of 3/5" MDF, and built a CNC machine.

At the time, however, neither of us were old enough to drive, so we had to

tie the MDF to my bike, and run it back to his house. The CNC machine

worked, but we were both hired by Mindcraft Makerspace within the month

and the laser cutters there made our CNC machine pale in comparison.

Over the last few years I've accumulated several kilograms of PLA scraps

from failed 3D prints, and I needed a way to recycle them. PLA filament

costs $25 per kilogram, so when I heard that it could be recycled, I built

a small single-screw extruder. The rig worked, but to get high quality

filament, the pieces of plastic fed into the extruder had to be really

small. The next leg of this project will be to design a plastic grinder.

Over the last few years I've accumulated several kilograms of PLA scraps

from failed 3D prints, and I needed a way to recycle them. PLA filament

costs $25 per kilogram, so when I heard that it could be recycled, I built

a small single-screw extruder. The rig worked, but to get high quality

filament, the pieces of plastic fed into the extruder had to be really

small. The next leg of this project will be to design a plastic grinder.

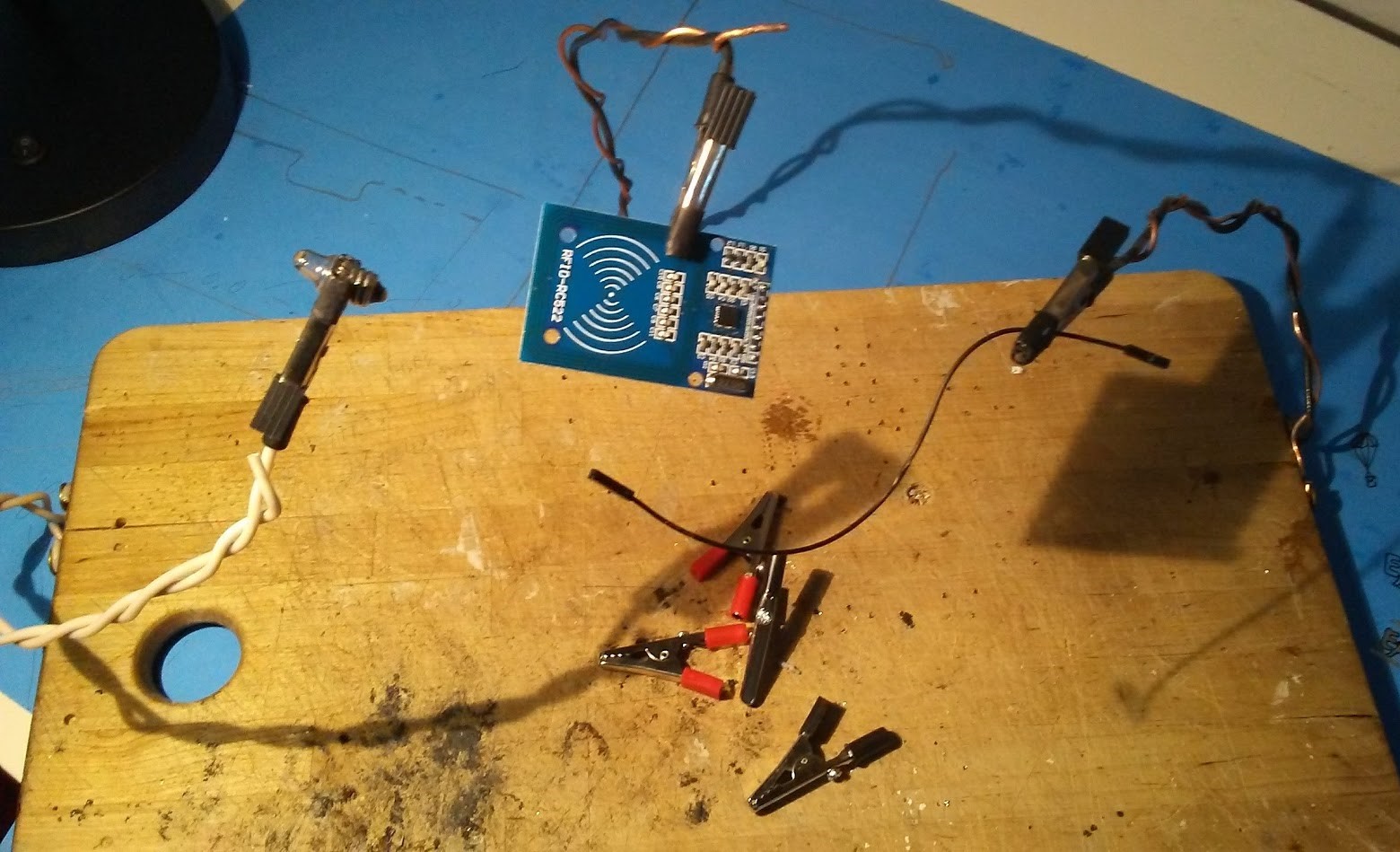

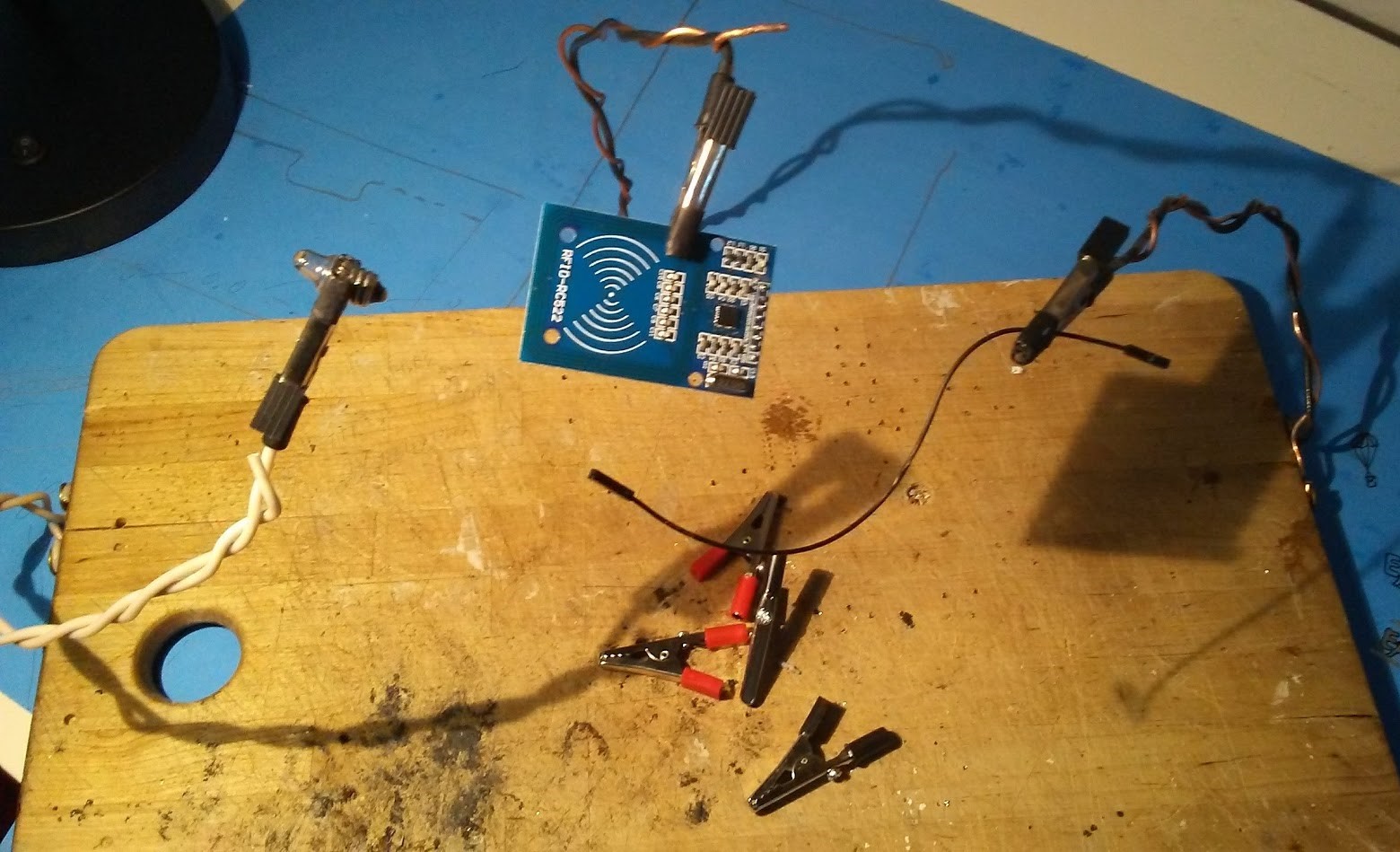

The first time I used a third arm for soldering, I knew I had to have one.

In true maker spirit, I decided that buying aligator clips on Amazon

would be cheaper than buying a third arm. I crimped the clips to two

12 gauge wires wrapped around each other, and covered each of the teeth with

heat shrink, and voila! Functional 3rd arm! I bolted three arms to my

work surface (an old cutting board), and I was ready to go.

The first time I used a third arm for soldering, I knew I had to have one.

In true maker spirit, I decided that buying aligator clips on Amazon

would be cheaper than buying a third arm. I crimped the clips to two

12 gauge wires wrapped around each other, and covered each of the teeth with

heat shrink, and voila! Functional 3rd arm! I bolted three arms to my

work surface (an old cutting board), and I was ready to go.

This project was, in every regard, my biggest failure (and that is saying

a lot). My biology teacher had asked me to build a spectrophotometer for the

school, which seemed simple enough. For those who are unfamiliar, a

spectrophotometer analyses the concentration of a sample by measuring the

transmittance of the sample as different wavelengths of light are shined

through it. Seems simple enough...

This project was, in every regard, my biggest failure (and that is saying

a lot). My biology teacher had asked me to build a spectrophotometer for the

school, which seemed simple enough. For those who are unfamiliar, a

spectrophotometer analyses the concentration of a sample by measuring the

transmittance of the sample as different wavelengths of light are shined

through it. Seems simple enough...

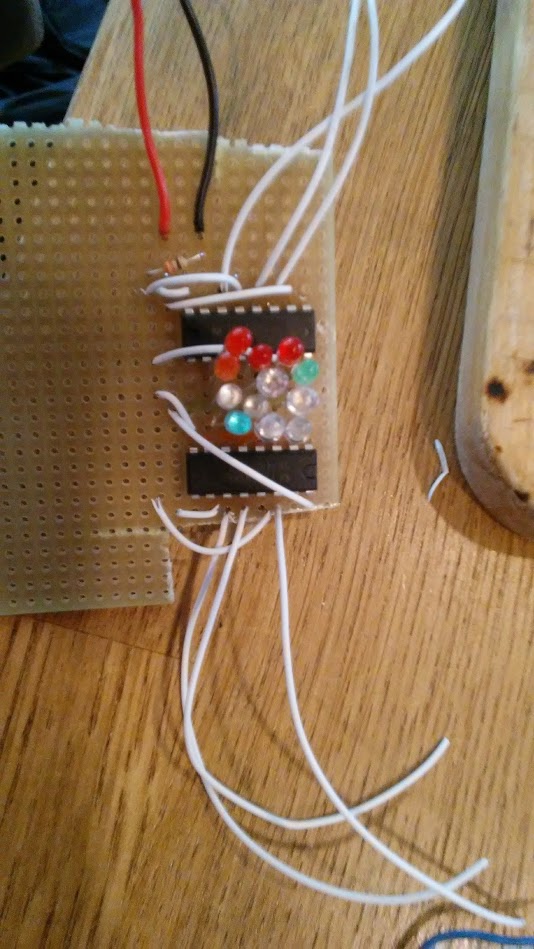

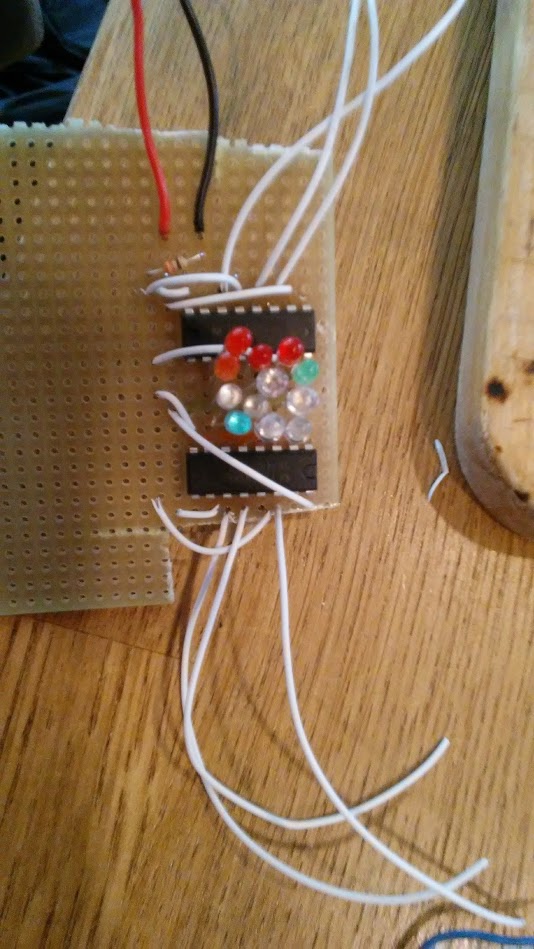

I mounted a fragment of a CD onto a servo motor, wired an incandescent bulb

(for full wavelength) to an arduino set up with a photocell, and measured

the absorbance as the servo moved a spectrum across the photocell. Nothing.

This first attempt is the topmost picture above. When that didn't work, I

decided to pursue a finite number of datapoints by using LEDs. I designed

a new circuit to light one LED at a time and measure that absorbance, and

I built it on protoboard (having been freshly traumatized by the

STM breadboard) and it worked! All I had left to do was replace my Arduino

Uno with the smaller Adafruit Pro Trinket!

I did not know that the Pro Trinket does not have serial communication.

After a week or so of trying to solve the why-can't-I-access-the-readings

problem, I destroyed the bootloaded and never succeeded in reloading it

(I needed the very FTDI cable that could have saved me all that trouble in

the first place). By that time I had run out of energy and transferred to

East High School, so I gave up. If I have time, I would really like to

take on this project again, with better judgement and more experience.

The seawater is stored in one side, the valves are closed, and a pump attached

to the vacuum hose is used to decrease the pressure in the apparatus to

the about 21 mmHg, or the vapor pressure of water. When this pressure is

reached, the water will boil until the pressures equalize again. If one

side is heated and the other is not (accomplished by painting one side black

and the other silver), then the water in the hot side will boil, reach the

refrigeration coil, and condense into the other side.

The seawater is stored in one side, the valves are closed, and a pump attached

to the vacuum hose is used to decrease the pressure in the apparatus to

the about 21 mmHg, or the vapor pressure of water. When this pressure is

reached, the water will boil until the pressures equalize again. If one

side is heated and the other is not (accomplished by painting one side black

and the other silver), then the water in the hot side will boil, reach the

refrigeration coil, and condense into the other side.

The final parts list was:

The final parts list was:

All in all, the project only took one day to complete (excluding testing).

All in all, the project only took one day to complete (excluding testing).

Of course, this prototype is not suitable for continued use - the pcv would

deteriorate in the sun and the volume is too small - but it will work well

for testing. The saltwater side (with the ball and socket valve) will be

painted black so it heats up in the sun, and the volume of water in the

other side will be used to determine the efficiency over time.

Of course, this prototype is not suitable for continued use - the pcv would

deteriorate in the sun and the volume is too small - but it will work well

for testing. The saltwater side (with the ball and socket valve) will be

painted black so it heats up in the sun, and the volume of water in the

other side will be used to determine the efficiency over time.

I could now crush water bottles, but without the one way valve at the

bottom, I couldn't get more than one stroke. To fix this, I used NighHawkInLight's design

for one way valves with some pieces of an inner tube for a bike, and it worked

splendidly!

I could now crush water bottles, but without the one way valve at the

bottom, I couldn't get more than one stroke. To fix this, I used NighHawkInLight's design

for one way valves with some pieces of an inner tube for a bike, and it worked

splendidly!

Now I'm only waiting for a new negative pressure gauge: after that arrives,

I can begin testing.

Now I'm only waiting for a new negative pressure gauge: after that arrives,

I can begin testing.

We decided that it would be easier to manage and test the computer if we

created a printed circuit board for it, especially given my experience with

the breadboard STM. I had only very limited experience with etching

PCBs using ferric chloride, and even less with

We decided that it would be easier to manage and test the computer if we

created a printed circuit board for it, especially given my experience with

the breadboard STM. I had only very limited experience with etching

PCBs using ferric chloride, and even less with

This is the PCB while it was being etched in a 60 watt Epilog Fusion. By

cutting a rectangle with the dimensions of the PCB blank, pretty precise

alignment is possible. When one side was finished, the PCB was flipped over

to etch the opposite side.

This is the PCB while it was being etched in a 60 watt Epilog Fusion. By

cutting a rectangle with the dimensions of the PCB blank, pretty precise

alignment is possible. When one side was finished, the PCB was flipped over

to etch the opposite side.

After etching and assembling this PCB, we realized that our sensors were

all digital devices, not analog ones. We are still in the process of creating

a new revision.

After etching and assembling this PCB, we realized that our sensors were

all digital devices, not analog ones. We are still in the process of creating

a new revision.

Scattercloud is, at its simplest, a blockchain. The scatter.cloud blockchain

(hereafter SCA) is designed to facilitate fast and byzantine fault tolerant

transactions between clients on the network, using a derived consensus model

for mitigating forks in the blockchain. Information on the development of

SCA will be posted here, as well as code and instructions for accessing and

developing on the blockchain.

Scattercloud is, at its simplest, a blockchain. The scatter.cloud blockchain

(hereafter SCA) is designed to facilitate fast and byzantine fault tolerant

transactions between clients on the network, using a derived consensus model

for mitigating forks in the blockchain. Information on the development of

SCA will be posted here, as well as code and instructions for accessing and

developing on the blockchain.

These pictures show a phone camera mount for a microscope that I designed in

FreeCAD. The mount is inspired by

These pictures show a phone camera mount for a microscope that I designed in

FreeCAD. The mount is inspired by  The disk is designed to fit inside the diaphragm of a Zenith microscope,

so that a user can switch between darkfield and brightfield by rotating the

diaphragm. Here are the results:

The disk is designed to fit inside the diaphragm of a Zenith microscope,

so that a user can switch between darkfield and brightfield by rotating the

diaphragm. Here are the results:

These images are good for illustrating the differences between the two

microscopes, but they are poorly focused (my piece of tissue paper was not

very flat). Better clarity can be achieved using a slide and a smaller

sample:

These images are good for illustrating the differences between the two

microscopes, but they are poorly focused (my piece of tissue paper was not

very flat). Better clarity can be achieved using a slide and a smaller

sample:

The details become much easier to see under a darkfield microscope (and they

look cooler too!). The file for the occulting disk is

The details become much easier to see under a darkfield microscope (and they

look cooler too!). The file for the occulting disk is  This image shows the contrast between the flourescent (highlighted)

and normal fibers in a brightfield microscope. The image is poorly focused

because the sample was too large, and the highlighter prevented me from using

water or a coverslip.

This image shows the contrast between the flourescent (highlighted)

and normal fibers in a brightfield microscope. The image is poorly focused

because the sample was too large, and the highlighter prevented me from using

water or a coverslip.

It worked! Sort of. Although the highlighted side is much more clearly distinguishable,

ideally, the non-flourescent areas should be invisible. Additionally, using

a filter to create high frequency light assumes that the microscope's bulb

already produces light of that wavelength. I removed the lens on the bulb on the

AmScope microscope, and its tungsten filament bulb worked. The Zenith school

microscopes did not work so well.

It worked! Sort of. Although the highlighted side is much more clearly distinguishable,

ideally, the non-flourescent areas should be invisible. Additionally, using

a filter to create high frequency light assumes that the microscope's bulb

already produces light of that wavelength. I removed the lens on the bulb on the

AmScope microscope, and its tungsten filament bulb worked. The Zenith school

microscopes did not work so well.

The filter significantly decreases the brightness of the LED, and the datasheet

indicates that very nearly 100% of light under 500nm is blocked out, so

the remaining light should all be a result of a wider wavelength range coming

from the LED.

The filter significantly decreases the brightness of the LED, and the datasheet

indicates that very nearly 100% of light under 500nm is blocked out, so

the remaining light should all be a result of a wider wavelength range coming

from the LED.

The led did create more contrast (using a different sample, obviously),

but light pollution (if you will) from the LED that was not blocked by the

filter made the sample hard to look at. Using a darkfield occulting disk

in conjunction with the LED did a lot to solve this problem.

The led did create more contrast (using a different sample, obviously),

but light pollution (if you will) from the LED that was not blocked by the

filter made the sample hard to look at. Using a darkfield occulting disk

in conjunction with the LED did a lot to solve this problem.

This modification works even without the lense, depending on the sample.

More work will be done to create cheaper and more effective longpass filters,

ideally with adjustable thresholds for use with different indicators. It is

important to note that this microscope only works in the dark, or with a

towel or jacket wrapped around the stage and objective lenses.

This modification works even without the lense, depending on the sample.

More work will be done to create cheaper and more effective longpass filters,

ideally with adjustable thresholds for use with different indicators. It is

important to note that this microscope only works in the dark, or with a

towel or jacket wrapped around the stage and objective lenses.

At the heart of the STM is a piezo amplifier. They are used to build impact

sensors and guitar amplifiers and they are extremely cheap: I purchased this

bag of 20 on ebay for only $3. The thin white layer on the piezo disk is

piezoelectric ceramic, which flexes when electricity is passed through it.

John Alexander showed that by cutting the ceramic into four quarters, the

disk could be made to flex in a specific way.

At the heart of the STM is a piezo amplifier. They are used to build impact

sensors and guitar amplifiers and they are extremely cheap: I purchased this

bag of 20 on ebay for only $3. The thin white layer on the piezo disk is

piezoelectric ceramic, which flexes when electricity is passed through it.

John Alexander showed that by cutting the ceramic into four quarters, the

disk could be made to flex in a specific way.

An atomically-sharp tip is made by shattering tungsten wire with a set

of wire cutters, and then mounted on the center of the piezo disk. An

oscilloscope sends a sine wave to the piezo scanner, which moves back and

forth, and the current flowing from the tip to the sample surface is

amplified and measured, which creates an image. I used John Alexander's

amplifier circuit because it is simpler, albeit less refined, and remade the

circuit on Fritzing to prepare it for breadboarding (yep, I did that).

An atomically-sharp tip is made by shattering tungsten wire with a set

of wire cutters, and then mounted on the center of the piezo disk. An

oscilloscope sends a sine wave to the piezo scanner, which moves back and

forth, and the current flowing from the tip to the sample surface is

amplified and measured, which creates an image. I used John Alexander's

amplifier circuit because it is simpler, albeit less refined, and remade the

circuit on Fritzing to prepare it for breadboarding (yep, I did that).

These are my adaptations of John Alexanders XY Controller (top) and amplifier

(bottom) circuits, done in Fritzing. These schematics are ideantical to those

published on

These are my adaptations of John Alexanders XY Controller (top) and amplifier

(bottom) circuits, done in Fritzing. These schematics are ideantical to those

published on  Everything about this design is inspired by Dan Berard's STM, with acrylic

plates for vibration isolation and three BYJ-48 stepper motors instead of

one for full range of motion. The STEP file for this design is available

Everything about this design is inspired by Dan Berard's STM, with acrylic

plates for vibration isolation and three BYJ-48 stepper motors instead of

one for full range of motion. The STEP file for this design is available

To further isolate vibrations, I used sections cut from three drywall anchors

to couple the stepper motors to the actuators. Now it was time for electronics:

To further isolate vibrations, I used sections cut from three drywall anchors

to couple the stepper motors to the actuators. Now it was time for electronics:

A relatively simple circuit became incredibly hard to manage when built on

a breadboard. After hours of finding problems and adjusting component positions,

I finally recieved a signal. I combined the electronics with the mechanical

components, and I was ready to run my first test.

A relatively simple circuit became incredibly hard to manage when built on

a breadboard. After hours of finding problems and adjusting component positions,

I finally recieved a signal. I combined the electronics with the mechanical

components, and I was ready to run my first test.

The Arduino Mega acted as the oscilloscope required to send a signal to the

probe, while an Arduino Uno measured the signal from the amplifier circuit.

A script written in Processing showed the oscilloscope readings on my computer

screen. The BYJ-48 Happy Drivers are disconnected after homing to prevent

wobble, an idea suggested by Dan Berard.

The Arduino Mega acted as the oscilloscope required to send a signal to the

probe, while an Arduino Uno measured the signal from the amplifier circuit.

A script written in Processing showed the oscilloscope readings on my computer

screen. The BYJ-48 Happy Drivers are disconnected after homing to prevent

wobble, an idea suggested by Dan Berard.

The first image shows the readings when power is first sent to the STM,

after which it begins scanning. The second shows the reading I received

after accidentally crashing the tip into the sample (a piece of flattened

copper wire). It is quite likely that these readings are entirely insignificant,

or merely due to static.

The first image shows the readings when power is first sent to the STM,

after which it begins scanning. The second shows the reading I received

after accidentally crashing the tip into the sample (a piece of flattened

copper wire). It is quite likely that these readings are entirely insignificant,

or merely due to static.

The parts for the kite include a few sticks (I had three carbon fiber

tubes laying around, but they certainly aren't necessary), a trash bag,

some tape, string, and three sheets of paper. Tape the sticks together to

form a diamond, and cut open the trash bag.

The parts for the kite include a few sticks (I had three carbon fiber

tubes laying around, but they certainly aren't necessary), a trash bag,

some tape, string, and three sheets of paper. Tape the sticks together to

form a diamond, and cut open the trash bag.

Cut the trash bag to fit around the cross, and attach a length of string

to the cross spar.

Cut the trash bag to fit around the cross, and attach a length of string

to the cross spar.

A piece of tape on the inside of the string keeps it from falling inward.

To create a streamer, remove the drawstring from the bag (you might have

to cut it in half), and tape it to the bottom of the kite. Cut a sheet

of paper in half, and crumple the middle until it forms a bow. Repeat

these steps until you have six bows, then tape these to the streamer. The

kite is ready to fly!

A piece of tape on the inside of the string keeps it from falling inward.

To create a streamer, remove the drawstring from the bag (you might have

to cut it in half), and tape it to the bottom of the kite. Cut a sheet

of paper in half, and crumple the middle until it forms a bow. Repeat

these steps until you have six bows, then tape these to the streamer. The

kite is ready to fly!

The FPV setup is also incredibly simple. I 3D printed a set of VR goggles

from

The FPV setup is also incredibly simple. I 3D printed a set of VR goggles

from  The camera was the cheapest I could find on the internet, so the images

aren't great, but they are still pretty entertaining:

The camera was the cheapest I could find on the internet, so the images

aren't great, but they are still pretty entertaining:

Of course, it is nice to have control over your direction, and for that,

we have drones. Due to the popularity of drone piloting, building and

flying all kinds of drones is pretty straightforeward. My best-documented

drone project was for an engineering class in 2017.

Of course, it is nice to have control over your direction, and for that,

we have drones. Due to the popularity of drone piloting, building and

flying all kinds of drones is pretty straightforeward. My best-documented

drone project was for an engineering class in 2017.

This drone was built from parts scavenged from other drones, fit into

a body that was stress tested and designed for weight. The body was

designed in an educational version of Autodesk Inventor Professional

CAD software.

This drone was built from parts scavenged from other drones, fit into

a body that was stress tested and designed for weight. The body was

designed in an educational version of Autodesk Inventor Professional

CAD software.

After 3D printing, each of the parts snapped in, the battery was glued on

top, and the drone flew!

After 3D printing, each of the parts snapped in, the battery was glued on

top, and the drone flew!

Recently, I became more interested in building rc planes instead of quadcopters

because of greater efficiency and load capacity. I don't have pictures of all

the builds, but here are each of the finished planes (not all of which flew).

Recently, I became more interested in building rc planes instead of quadcopters

because of greater efficiency and load capacity. I don't have pictures of all

the builds, but here are each of the finished planes (not all of which flew).

It's pretty obvious why this plane didn't fly. The enormous battery on the

nose threw it into a dive within a few seconds of launch every time.

It's pretty obvious why this plane didn't fly. The enormous battery on the

nose threw it into a dive within a few seconds of launch every time.

After my failure with the first flying wing, I decided to go back to the

basics. My friend and I built the

After my failure with the first flying wing, I decided to go back to the

basics. My friend and I built the  This was the ultimate glider project. Designed after the Horton H IV, this

glider was built out of choroplast for stiffness and waterproofing, and

could support a pushed propeller as well. The plan is to tow this plane

behind a kite, then release it with a servo and fly it to the ground using a

remote control.

This was the ultimate glider project. Designed after the Horton H IV, this

glider was built out of choroplast for stiffness and waterproofing, and

could support a pushed propeller as well. The plan is to tow this plane

behind a kite, then release it with a servo and fly it to the ground using a

remote control.

The glider is built with a steep airfoil and dihedral wings for stability at

low speeds, and uses only three channels. Like the flying wing, the elevator

and aileron functions are combined using a V-Tail mixer.

The glider is built with a steep airfoil and dihedral wings for stability at

low speeds, and uses only three channels. Like the flying wing, the elevator

and aileron functions are combined using a V-Tail mixer.

This project was done with my sister on a weekend with nothing else to do. We

removed the electronics from a cheap 2 channel RC car, and replaced the

electromagnet used for steering with a small dc motor from a drone. We fixed

propellers onto each of the motors' shafts, and attached them, at right angles,

to the bottom of a helium balloon we bought at a grocery store. By adding coins,

we could make the balloon slightly less than neutrally bouyant, and by angling the

propeller downward, we could control both the height and the foreward

velocity of the balloon simultaneously. The othe rmotor was used for steering.

This project was done with my sister on a weekend with nothing else to do. We

removed the electronics from a cheap 2 channel RC car, and replaced the

electromagnet used for steering with a small dc motor from a drone. We fixed

propellers onto each of the motors' shafts, and attached them, at right angles,

to the bottom of a helium balloon we bought at a grocery store. By adding coins,

we could make the balloon slightly less than neutrally bouyant, and by angling the

propeller downward, we could control both the height and the foreward

velocity of the balloon simultaneously. The othe rmotor was used for steering.

The blimp flew remarkably well. The incredibly slow speed and low risks

involved with collisions meant that it was not as difficult to fly as one

might expect (untill all of the helium leaked out of the mylar).

The blimp flew remarkably well. The incredibly slow speed and low risks

involved with collisions meant that it was not as difficult to fly as one

might expect (untill all of the helium leaked out of the mylar).

These are the only things you need to make rocket candy, in fact, you could

probably get away with just the potassium nitrate and sugar. The postassium

nitrate is a strong oxidizing agent: when it is added to the sugar (which

would burn slowly anyway) it speeds up the reaction to the point where

the exhaust gasses produce meaningful thrust.

These are the only things you need to make rocket candy, in fact, you could

probably get away with just the potassium nitrate and sugar. The postassium

nitrate is a strong oxidizing agent: when it is added to the sugar (which

would burn slowly anyway) it speeds up the reaction to the point where

the exhaust gasses produce meaningful thrust.

I started by making a bunch of paper mache tubes for the motors, each with

a capacity of 5ml. This proved to be a mistake, because the tiny surface

area of the fuel column caused an extremely slow burn rate.

I started by making a bunch of paper mache tubes for the motors, each with

a capacity of 5ml. This proved to be a mistake, because the tiny surface

area of the fuel column caused an extremely slow burn rate.

As it turns out, black iron oxide is the key ingredient in a lot of toners,

which explains the inky black color. After adding the melted sugar (outside,

wearing PPE and with a fire extinguisher handy), it was time to fill the

tubes with rocket fuel.

As it turns out, black iron oxide is the key ingredient in a lot of toners,

which explains the inky black color. After adding the melted sugar (outside,

wearing PPE and with a fire extinguisher handy), it was time to fill the

tubes with rocket fuel.

This was not as easy as I thought it would be. As the sugar cooled, the

fuel became hard and chunky, so it was difficult to pack into the tiny

tubes. Additionally, the fuel was extremely sticky and it would stain anything

it came into contact with.

This was not as easy as I thought it would be. As the sugar cooled, the

fuel became hard and chunky, so it was difficult to pack into the tiny

tubes. Additionally, the fuel was extremely sticky and it would stain anything

it came into contact with.

When all the fuel was packed into tubes, I wrapped them in one more sheet

of blank paper, and they were ready for testing.

When all the fuel was packed into tubes, I wrapped them in one more sheet

of blank paper, and they were ready for testing.

It is illegal to launch a rocket with a custom motor (like the ones I built)

in the United States without a liscence, which I am inelligible for because

I am not yet 18. It is not illegal, however, to burn these motors on the ground,

so I built a small mount using a few bricks and tested them in my backyard.

It is illegal to launch a rocket with a custom motor (like the ones I built)

in the United States without a liscence, which I am inelligible for because

I am not yet 18. It is not illegal, however, to burn these motors on the ground,

so I built a small mount using a few bricks and tested them in my backyard.

As you can see, the motors did not produce spectacular plumes of exhaust.

This is a consequence of two things: first, the rediculously small amount

of fuel in a long tube yielded a long burn time with very little thrust.

Additionally, the paper mache tubes were not completely dry, so they did

not burn away as they should have.

As you can see, the motors did not produce spectacular plumes of exhaust.

This is a consequence of two things: first, the rediculously small amount

of fuel in a long tube yielded a long burn time with very little thrust.

Additionally, the paper mache tubes were not completely dry, so they did

not burn away as they should have.

My reactor was built from a bucket with a refrigeration coil flare-fitted

to the lid. This provided an airtight reaction chamber that could be easily

opened and inspected, although soldering the flare fitting to the lid of

the paint can was not easy. I ran the refrigeration coil through a bucket

of water to enhance cooling, but removed it later because condensed

gas in the coil in the bucket caused a rise in pressure in the container.

My reactor was built from a bucket with a refrigeration coil flare-fitted

to the lid. This provided an airtight reaction chamber that could be easily

opened and inspected, although soldering the flare fitting to the lid of

the paint can was not easy. I ran the refrigeration coil through a bucket

of water to enhance cooling, but removed it later because condensed

gas in the coil in the bucket caused a rise in pressure in the container.

I managed to extract about 60ml of gas from a few apple cores, dried leaves

and sticks, and 30ml from scrap PLA from 3D prints. I did not control for

input volume so these numbers do not reflect efficiencies.

I managed to extract about 60ml of gas from a few apple cores, dried leaves

and sticks, and 30ml from scrap PLA from 3D prints. I did not control for

input volume so these numbers do not reflect efficiencies.

I did note a huge difference in color between the PLA and organic matter -

the PLA produced a much clearer oil. This is most likely attributable to the